Mad Dog Phase 2 is located in water depths of 1,370m to 2,200m in the Green Canyon area in the Gulf of Mexico, approximately 190 miles south of New Orleans, Louisiana, US.

The project is a southern and southwestern extension of the existing BP-operated Mad Dog offshore oil and gas field, which was discovered in 1998 and started production in 2005.

BP operates the Mad Dog field with a 60.5% interest while BHP Billiton and Union Oil Company of California, an affiliate of Chevron USA, hold 23.9% and 15.6% interest in the field, respectively.

The entire Mad Dog area is estimated to hold four billion barrels of oil equivalent (Bboe). The production capacity of the current Mad Dog platform is up to 80,000 gross barrels of oil and 60 million gross cubic feet (MMcf) of natural gas per day. BP estimates a production capacity between 120,000boe and 140,000boe a day from the new development.

Mad Dog Phase 2 project timeline

Initial development plans of the project involved a spar designed by Technip similar to the one used in Phase 1. In 2013, the plan was scrapped due to spiralling costs that were estimated to be $22bn.

A revised plan for the development of Mad Dog Phase 2 was submitted to the US Bureau of Ocean Energy Management in August 2014, which received approval in March 2015. The new plan reduced the development cost to $14bn, which was further reduced to $9bn.

BP reached a final investment decision (FID) for the development of the project in December 2016. BHP Billiton decided to spend a capital of $2.2bn for its share of the development of the Mad Dog Phase 2 project in February 2017. Chevron reached an FID for the project late in February 2017.

Production from the field is expected to commence by the end of 2021.

Mad Dog Phase 2 development details

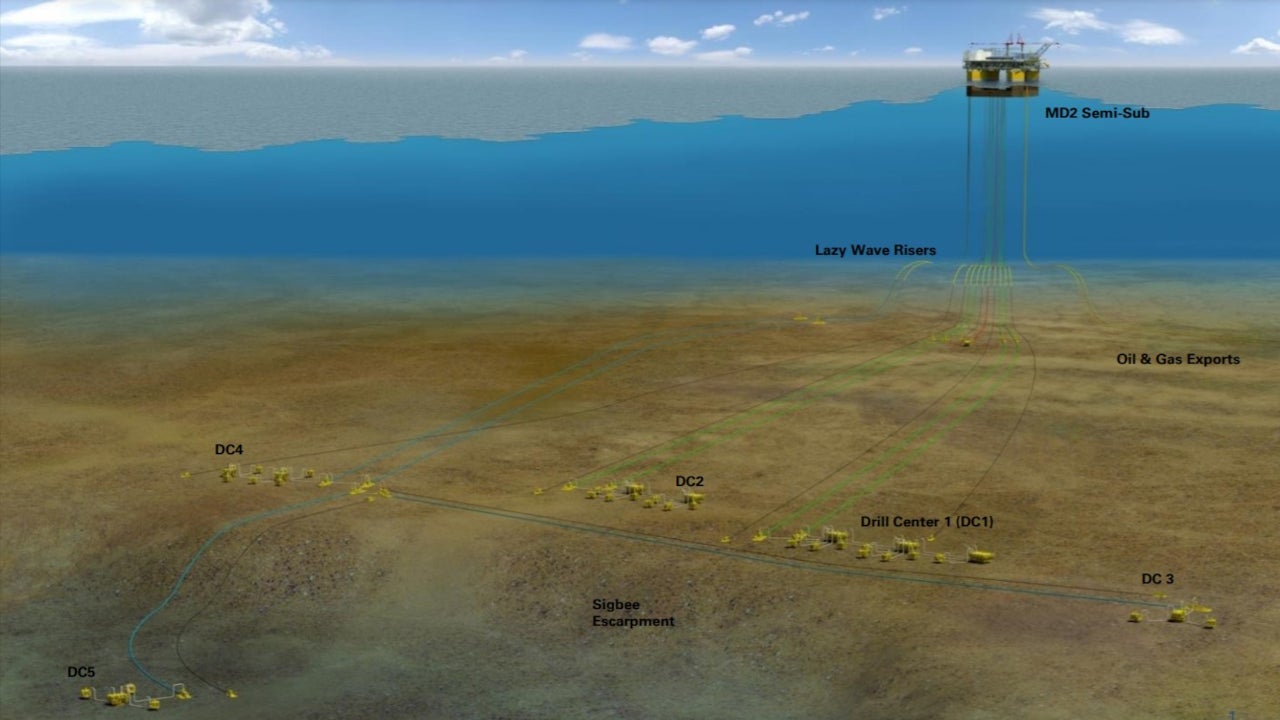

The Mad Dog Phase 2 development involves the drilling of 29 wells, including 17 wet-tree producers and 12 wet-tree injectors from five drill centres located in blocks 825 and 870. Front-end engineering and design (FEED) work on the project started in the third quarter of 2014.

A new integrated semi-submersible floating production platform with a production capacity of up to 140,000 gross barrels of crude oil per day (bpd) will be moored in 4,440ft deep water in the Green Canyon in block 780, west of the existing Mad Dog spar.

The platform design was inspired by the BP-operated Atlantis semi-submersible platform that reduced the weight of the topsides to 25,000t. It will also integrate the topside infrastructure with the jacket structure.

A water-flood project based on BP’s LoSal flooding technology was planned to enhance oil recovery from the field. It will handle 280,000b/d of low-salinity waterflooding. Oil produced from the field will be transported to the Mardi Gras pipelines.

Mad Dog Phase 1 development details

Phase 1 development of the field included a floating truss spar equipped with production and drilling facilities.

A third-party operator is the recipient of the oil and gas produced at the field, transported via the Caesar (oil) pipeline and the Cleopatra (gas) pipeline systems.

Contractors involved

FMC Technologies was contracted to manufacture and supply subsea equipment, including subsea trees, manifolds, and jumpers.

KBR and its Swedish subsidiary GVA will construct the production platform. The companies also won a contract for pre-FEED, FEED and execution stage support.

AMEC was selected to provide FEED services for the topside facilities of the project related to the spar concept.

Subsea 7 was awarded the engineering, procurement, construction and installation (EPCI) of the subsea umbilicals, risers and flowlines (SURF) and associated subsea architecture.

Schlumberger OneSubsea, Subsea 7’s Subsea Integration Alliance partner, was awarded the contract for the subsea production systems.