Co.L.Mar is a specialist provider of acoustic subsea leak detection equipment and noise assessment services for underwater applications.

The company has been operating in the marine industry since 1982 and is experienced in acoustic engineering, and geophysical investigations. Co.L.Mar is certified ISO 9000 – 2008.

Subsea leak detection systems for pipelines and installations

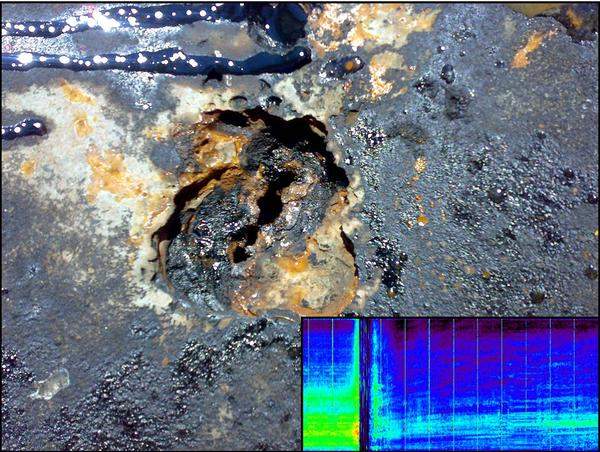

Co.L.Mar. has released an acoustic subsea leak detection system ALD® (acoustic leak detector) which is able to locate very small leaks on the sea line even in extremely hard environmental conditions. The system and the relative service have been developed for many years and an international patent has been obtained.

It is currently one of the fastest, most accurate and reliable method for sea line leak inspection, especially when an emergency occurs. We are an international leader in this specialist area thanks to our decades of experience and history of delivering proven leak detection solutions.

In the many offshore inspection projects we have worked on worldwide, we have been able to detect leaks as small as 0.2lt/minute.

Underwater pipeline leak inspection

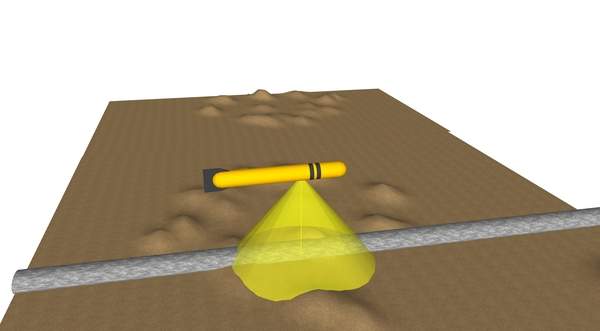

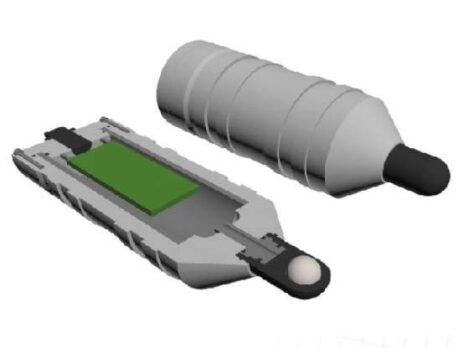

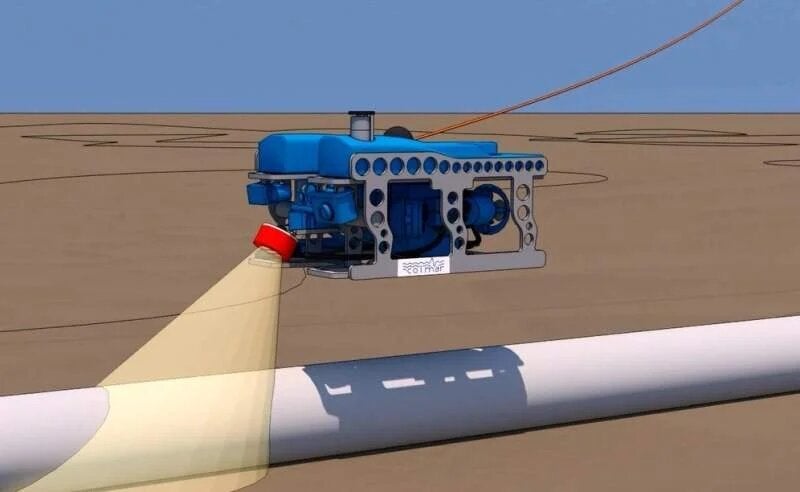

The ALD® underwater pipeline leak detection system features an underwater sensor that collects acoustic data as it scans the pipeline. The acoustic data is transferred online to an onboard receiver, then to a PC where is analysed, displayed and recorded by a proprietary software.

Compared with other leak detection techniques, ALD has the following advantages:

- Not affected by current, turbidity or pipeline burial

- No need to stop production

- High-sensitivity for small leak detection

- Reliability: as of May 2015, 100% rate of success

- Rapidity: fast mobilisation worldwide

- Zero environmental impact

- ROV, TOWED, DIVER, AUV inspection modes available

- We served SAIPEM, ExxonMobil, McDermott, SHELL, BP, PETRONAS, TOTAL, TECHNIP, BJ Services, FUGRO and HORIZON

Underwater leak detection and inspection techniques

During years of development, different underwater leak detection and inspection techniques have been defined:

- ROV inspection – the sensor is installed on the vehicle which follows the line at a speed of about 0.7kts

- TOWED FISH – the sensor, in a ‘fish’ configuration, is towed by a vessel along the pipeline track

- DIVER – the handheld sensor configuration is driven by a diver (suitable for flange inspections)

- AUV – a special version of ALD® can be easily fitted into any AUV payload

- VERTICAL DEPLOYMENT – the sensor is lowered from the boat in a line kept vertical by ballasts

ALD® as leak contingency plan during hydrotest

During hydrotest of subsea installation a leak contingency plan has to be put in place. This traditionally consists in injecting fluorescine or other kind of dye then proceeding with a visual inspection if required.

But in this case, very often the visual inspection fails because leaks on new installations are typically very small (FJ solder crack or leaking flange) and spotting any sign of dye became impossible. Not to mention if visibility is poor or some current or burial is present. As a consequence, we are often called out on a very urgent base after the failure of the hydrotest of the traditional visual inspection.

For this reason, many clients contract us to standby on-site during any hydrotest so that, with a small cost they can have the best leak detection service guaranteed in case of need.

Also dyes are pollutant and in many area of the world are interdicted, while ALD has zero environmental impact.

So we can provide a more effective and environmental-friendly leak contingency plan during pre-commissioning.

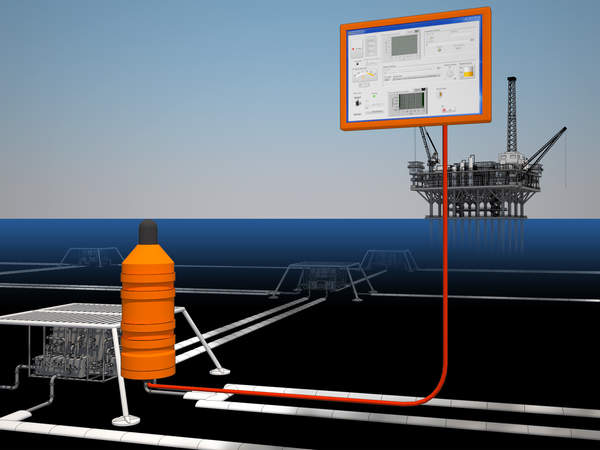

ALM acoustic leak monitoring of subsea installation

On the base of the experience gained in subsea leak inspection we have recently developed a system for permanent monitoring of the most critical areas of subsea installation: manifolds, wellhead, valves, etc.

The system is composed by one of more intelligent sensors to be installed subsea and of a surface station for settings and alarms generation. The subsea units are designed for 25-years life expectance with no maintenance and an operating depth of 2,500m.

Underwater noise measurement services

Co.L.Mar offers underwater noise assessment services that are backed up by our proprietary acoustic equipment and software. We design and build in-house our own acquisition equipment, and have the ability to customise and enhance existing technology for specialised operations.

We are experienced in assessing the acoustic impact of a wide range of man-made structures, including:

- Research vessels

- Submarines

- Platforms

- Barges

- Piling operations

- Racing boats

Our equipment can be rapidly deployed on small support vessels by our acoustic engineers. Once at the assessment site, we take water column temperature and salinity measurements. This data helps us to position the hydrophones at the correct depth for assessment.