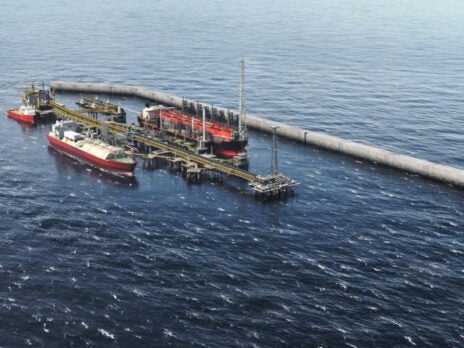

Bluewater designs, manufactures and supplies floating production, storage and offloading (FPSO) and single point mooring (SPM) systems for oil companies worldwide through turnkey supply and time charter contracts.

Floating production, storage and offloading systems

Bluewater has created, owned and operated ten floating production, storage and offloading systems (FPSOs), with three being retired and two sold back to oil companies.

The company also provides operational and logistic management and support for FPSO and FSO systems, and currently holds and operates five FPSOs.

Single point mooring systems

Bluewater has developed some of the most innovative SPM solutions, including catenary anchor leg mooring (CALM) buoys and tower, internal and external turret mooring systems.

Each type has its own characteristics and fields of application.

During the past 35 years, the company has created and delivered more than 100 CALM buoy systems and 25 tower and turret mooring systems, which include internal, external, fixed and disconnectable types.

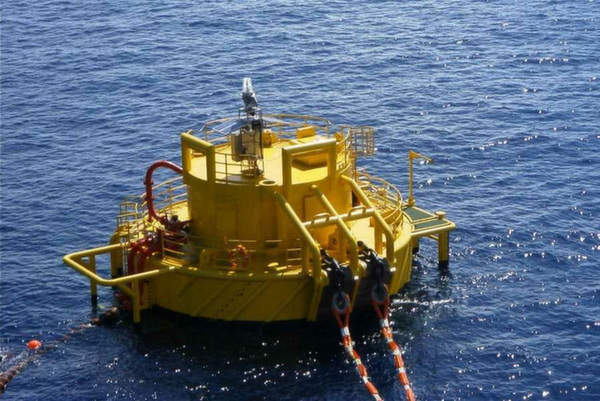

CALM buoy systems

The CALM buoy system is a buoy permanently moored to the seabed using multiple mooring lines. It facilitates near shore and offshore loading / offloading of trading tankers.

The buoy contains a bearing system that allows a part of it to rotate around the moored geostatic part. A tanker moored to this rotating section is able to freely weathervane around the geostatic element of the buoy.

The fluid transfer system includes submarine hoses between the pipeline end manifold (PLEM) at the seabed and the buoy, and hoses between the buoy and the tanker.

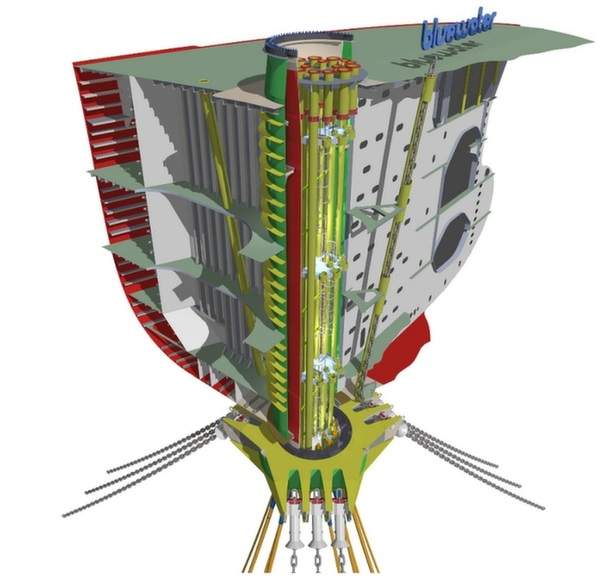

Turret mooring systems

The turret mooring system (TMS) consists of a turret assembly integrated with a vessel and fixed to the seabed by means of a mooring system. The TMS contains a bearing system that allows the vessel to rotate around the moored geostatic section of the turret.

The TMS includes a transfer system that enables connection of subsea pipelines and equipment to the weathervaning vessel such as an FSO or FSPO. The transfer system includes risers and umbilicals between subsea infrastructure and the geostatic area of the turret. Swivel modules forming part of the turret provide the transfer paths for fluids, gasses and power and control signals.

The TMS is fully passive and does not require active vessel heading control or active rotation systems.

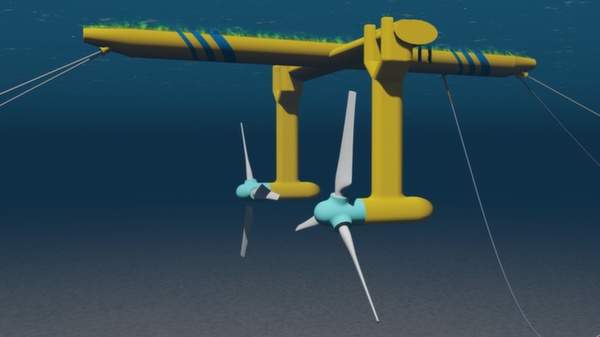

Tower mooring systems

The tower loading system consists of a tower structure that is permanently fixed to the seabed. The tower contains a bearing system that allows a segment of it to rotate around the fixed, geostatic part. A moored vessel is able to freely weathervaning around the fixed section of the base. A swivel in the tower provides the fluid, gas, power and signal transfer paths from rotating to geostatic.

A fluid transfer system enables connection of the vessel to the pipelines, which are connected at the base and swivels provide the fluid, gas, power and signal transfer paths in the tower.

Tower mooring systems are typically designed for shallow water depths and may include an ice-breaking cone structure to operate under arctic conditions. This enables the system to withstand ice on the move while being exposed to a temperature of up to -50°C.