With extensive experience in the development and application of wear and corrosion-resistant coatings for the protection of downhole directional drilling and subsea equipment components, Bodycote has established itself as one of the world leaders in coating services for the oil and gas industry.

The company’s field-proven range of thermal spray tungsten carbide coatings are the acknowledged industry standards for protection against wear due to abrasion, erosion and corrosion. Bodycote is also a technology leader in the development of abrasion and corrosion-resistant electrically insulating ceramic coatings.

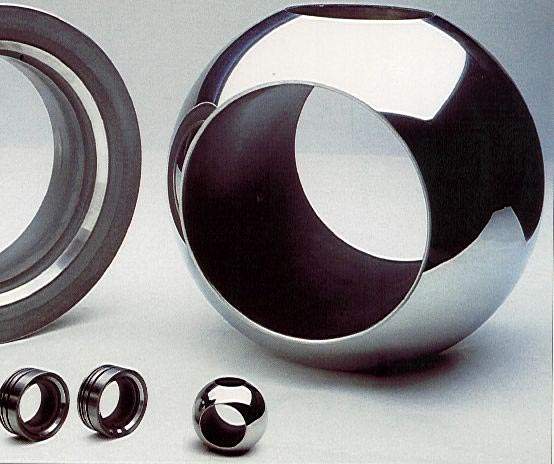

Wear and corrosion-resistant coating services

Bodycote uses the most sophisticated plant and equipment, offering plasma spraying, high-velocity oxy-fuel (HVOF) spraying, flame spraying, HVAF systems, automated surface activation, advanced robotic work handling and specialist diamond grinding and wire erosion finishing techniques. The company’s coating and finishing services are designed to accommodate a wide and varied range of component sizes, configurations and complexities.

Thermal spray tungsten carbide coatings

Typical applications that benefit from Bodycote’s range of HVOF and HVAF tungsten carbide coatings are:

- MTM technology ball valves and seats

- Gate valves

- Valve actuators

- Stems

- Mud pump sleeves, rods, plungers and rotors

- Drive shafts

- Enclosures

- Stabilisers

- Hydraulic rams

- Drilling tools

A full team of coating technologists and application engineers are on hand to offer expert advice on all aspects of Bodycote’s thermal spray coating technology. Support services include material selection, coating and application development, coating evaluation and qualification.

Specialist coating technologies

With a global network of accredited thermal processing facilities in 26 countries, Bodycote also offers other coating technologies that can be used in a wide range of surface engineering processes, including K-Tech, thin film ceramic technology, Sherardizing and Kolsterising.

Industry leading coating supplier

Bodycote is an industry leading supplier of specialist coatings which meet the demanding requirements of its offshore customers.

The company’s commitment to this sector is reinforced by its ISO 9001:2000, ISO 14001, OHSAS 18001 and Investors in People (IIP) accreditations. Bodycote holds Rolls Royce SABRe 9000, SNECMA, NADCAP and AS9100 programme accreditations.

We understand your challenges

Please provide Bodycote with your business enquiry, using the form below.