The EM&I Group has more than 30 years’ experience as an independent specialist supplier of asset integrity management, inspection, repair and maintenance services to large multinationals in the oil, gas and energy industries.

The company’s wider industrial experience from the marine, power generation, petrochemical, refinery, nuclear and aerospace industries brings effective, innovative solutions to each and every client.

EM&I currently operates in Angola, Australia, Brazil, Canada, China, Equatorial Guinea, France, Malaysia, New Zealand, Nigeria, Singapore, Vietnam, the UK and the US.

EM&I has developed a suite of services around their concept of ‘no drydock safely’. The holistic range of services offered, helps their clients avoid having to send their floating production assets to drydock, presenting a very clear business case on the financial savings.

EM&I also has an extensive track record of safely delivering complex repair and maintenance projects from the top of the flare to underwater structural replacements.

Hull inspection techniques and strategy (HITS)

Many FPSO, MODU, FLNG and FSRU operators expect to remain on station for extended periods of up to 25 years, and this brings a number of integrity and compliance challenges particularly in a climate of cost reduction.

A primary reason for coming off station is related to maintaining hull integrity and managing mooring / station keeping capability.

Regulators and class societies require operators to demonstrate the integrity of these key components and traditionally this was achieved by drydocking.

More recently alternative methods, such as divers or work-class ROVs, have been used but these solutions are costly and incur significant safety, commercial and technical risk.

The industry responded by forming the hull inspection techniques and strategy (HITS) JIP to look at ways of improving the approach to hull inspections and one of the key areas of focus was the inspection of the underwater hull.

The EM&I Group is a founder member of HITS and has been a market leader in asset integrity management services to the oil and gas industry for more than 30 years.

ODIN® – diverless hull inspection

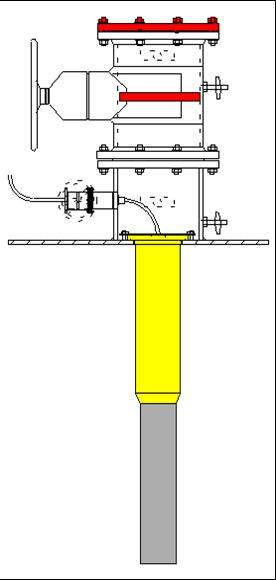

The development of ODIN, EM&I’s Diverless UWILD (underwater inspection in lieu of drydocking) methodology is an intrinsic part of the ‘No Drydock…Safely’ package.

ODIN is a complete hull structural integrity package which gives operators and regulators better information on hull condition.

It was demonstrated to class societies, regulators and operators worldwide in 2014 which led to acceptance by the major class societies and Bahamas Flag.

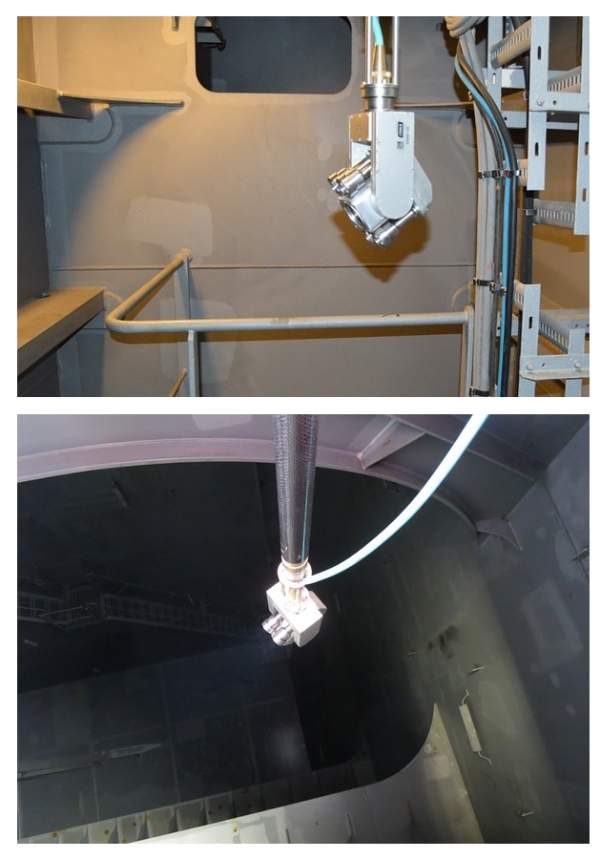

ODIN enables the inspection of the outside of the hull from within, avoiding removal of marine growth and avoiding damaging coatings.

The ODIN methodology was proven and refined on two operating FPSOs in Brazil in 2014 and two drillships in 2015. Orders have been placed for five more ODIN projects as part of fleet wide contracts for major FPSO and drilling organisations.

NoMan™ – remote inspection of confined spaces

The innovation has not stopped with ODIN – the HITS JIP identified that another key industry driver was reducing the need for man entry into confined spaces for inspection.

For example, inspection of hull internal tank structures using rope access teams is already being challenged by using ROVs in water ballast tanks, UAVs are also being tried out. However, the use of sophisticated cameras on carbon-fibre manipulators using laser scanning and photogrammetry is showing significant advantages.

These methods have ready applications to the increasing number of FLNG and FRSU assets that service the gas sector with additional innovations being developed such as backscatter computed tomography (BCT), a technique that can ‘see’ through multiple layers of different materials but only requiring access from one side.

HullGuard™ diverless corrosion protection

Many FPSOs use sacrificial anodes. These often need replacement over an extended field life through depletion or damage, carrying cost and safety penalties. Impressed Current Cathodic Protection requires regular maintenance using divers or ROVs.

HullGuard is designed to prevent corrosion to the hull and associated structures throughout the asset’s lifetime, but without the use of divers or ROVs for installation or maintenance.

EM&I offer a complete corrosion management service for hull integrity and topsides systems.

Inspection, repair and maintenance

EM&I inspectors meet and exceed the industry standard competency requirements for the task in hand. In instances where our innovative methods are ahead of the development of industry standards, we have developed internal training and certification procedures to ensure personnel competency.

EM&I have developed a wide range of innovative and award-winning inspection techniques, as well as using the latest technology available on the market.

Our objective is to provide you with the optimum inspection and survey solution.

EM&I services are backed by a solid engineering and innovative technology. We have developed specialised equipment and methods that are proven to deliver value and enhance safety.

Our experienced project management teams and documented systems means we efficiently manage multiple sub-contractors leaving you free to focus on your core business.

Safety and accreditation

EM&I has an excellent health and safety record and have been awarded the RoSPA gold medal four times as a result of eight consecutive gold awards for occupational health and safety. Other awards include the DTI Award for Safety Performance and the Seatrade Award for Innovation.

EM&I are accredited to ISO 9001: 2015 and inspection service standards are underpinned through the company’s ISO 17020 accreditation, allowing it to act as an independent inspection body.

The EM&I Group has a strong focus on innovation and continues to invest in improving integrity methods and enhancing safety, environmental and commercial performance – supporting the strategy of ‘No Drydock…Safely’

View our ‘Products and Services’ pages for more information. Please contact us for further information on any of our services.