Even under extreme operating conditions, J.D. Neuhaus hoists and cranes reliably move loads and are up to the job. They are in use in more than 70 different sectors, and are particularly in demand in the oil and gas exploration and processing sectors, in mining, heavy plant construction and the chemical industry.

At its Witten plant, J.D. Neuhaus produces pneumatically and hydraulically-operated hoists and crane systems. Thanks to this globally unique specialisation, JDN is not only a recognised expert in this field, but also the world market leader, with customers in more than 90 countries around the globe. Being a family company in our seventh generation – founded in 1745 – we offer guaranteed consistency and quality.

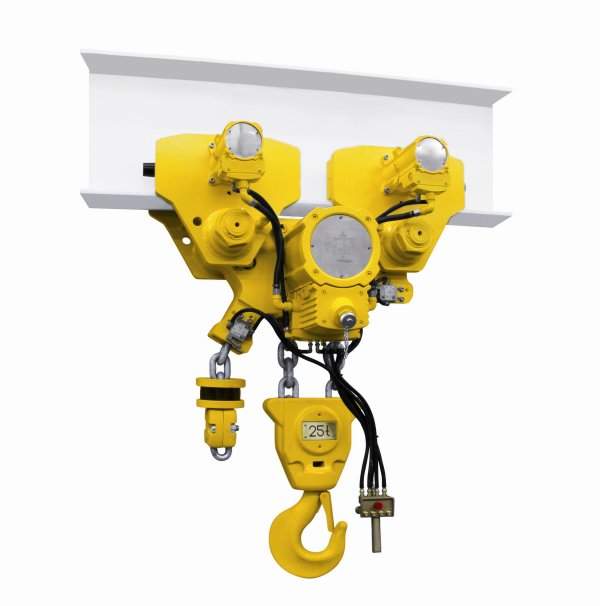

Lifting equipment: standard features and benefits

- Safety factor 5:1

- Tensile strength 3:1

- Tracebility by JDN unique parts marking system

- Overload adjustable from 90% to 125%

- True vertical lift

- Self-adjusting fail safe brake

- Integrated overload protection system from 1t upwards (EU version)

- (EU version)

- High performance multi-vane air motor with self-lubricating features and positive start-up system for a

- smooth start and consistent operation

- Explosion proof / spark resistant

- Ex-classification: Ex II 2 GD IIA T4/Ex II 3 GD IIB T4

- Temperature range: -20°C to +70°C

- ISO/FEM rating hoist: M3 (1 Bm)

- ISO/FEM rating chain: M3 (1 Bm)

- Trolleys with anti-drop and anti-climb devices

- All-steel cast iron construction

- Worldwide service

- ISO 9001

- ISO 14001

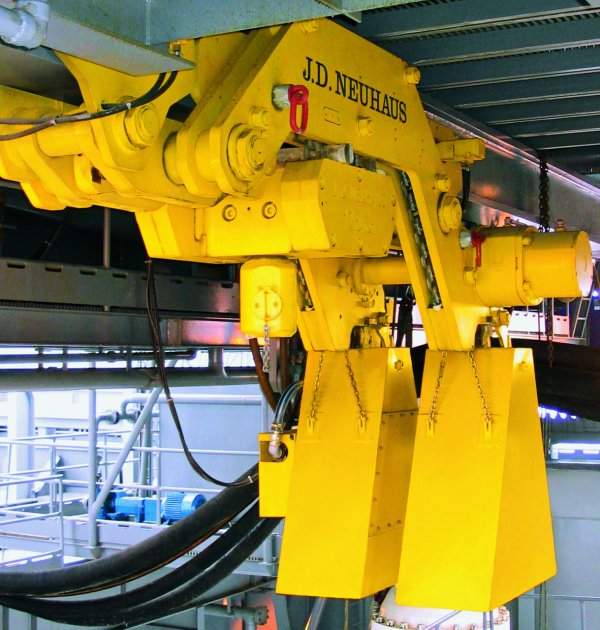

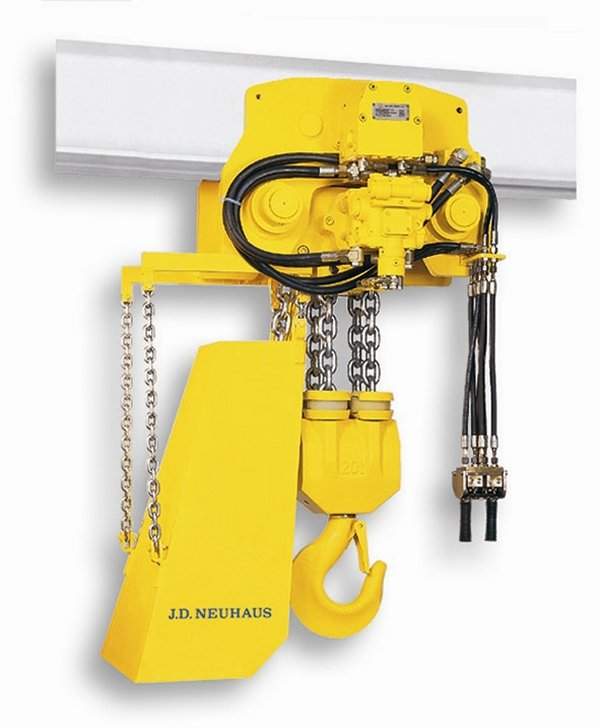

BOP handling systems

J.D. Neuhaus BOP handling systems are known for their reliable, robust and efficient operation on land, jack-up and semi-submersible drilling rigs. They have carrying capacities from 20t up to 200t.

The monorail hoists (EH) in our BOP handling systems feature a compact design with low headroom. They can be used as double lifting gear as in standard BOP handling systems or they can be connected by a coupling rod for use as a four-point BOP handling system. For extremely reduced spaces we recommend our ultra-low monorail hoists of the UH series.

Air and hydraulic-driven cranes and kits

JDN offers air and hydraulic-driven cranes suitable for working in hazardous areas as standard. The programme includes explosion-proof:

- Overhead travelling cranes

- Underslung cranes

- Slewing jib cranes

Subsea hoists

The JDN PROFI Subsea series is available with air or hydraulic drives. As well as a sensitive control system, the PROFI hoists are equipped with an overload protection. PROFI subsea hoists are a versatile and indispensable tool for professional divers and are suitable for horizontal work as well as for oblique pulling.

Cryogenic hoists for BOP handling in arctic areas

The temperature range of standard JDN hoists is -20°C to +70°C. JDN has developed hydraulic hoists for applications at temperatures as low as minus 45°C, such as BOP handling in arctic areas. JDN hydraulic hoists are designed to be operated with low-temperature hydraulic fluids and can be operated efficiently at temperatures from -45°C to +40°C.

Regulations

- DNV-OS-E101 – Drilling plant, October 2006

- FOR 1994-08-19 nr 820: Forskrift om maskiner

Design codes and standards

- DNV-OS-C101 – Design of Offshore steel Structure, General (LRFD Method), October 2008

- DNV 2.22 – Lifting Appliances, October 2008

- DNV-RP-C205 – Environmental conditions an environmental loads, April 2007

- DNV-OS-C103 – Structural design of column stabilised units (LRFD Method), October 2008

- FEM 1.001 – Rules for the design of Hoisting Appliances 1998.10.01

- Norsok R-CR-002 – Lifting equipment, January 1995

- Eurocode 3: Design of steel structures – Part 1-8: Design of joints, 16 April 2004

Notes

- Fabrication to comply with Norsok M-101

- Painting/Coating: Norsok M-501 Coating sys. no.1

- Sharp edges, fillets, corners and welds shall be rounded, minimum radius 2mm

- Material certificates acc. to NS-EN 10204. 3.1b or equal

- Material traceability required

- Welding by certified welders

- NDT requirements acc. to DNV 2.22 Lifting Appliances: All members are considered to be primary structure