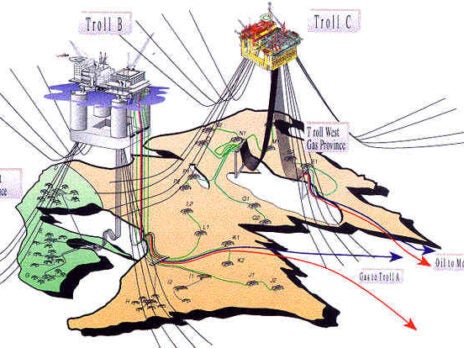

Markhus is an offshore and maritime related engineering company with experienced architects, engineers and draftsmen. Since the company was formed in 1984 we have specialised in architectural and structural engineering, project and discipline management as well as supply of complete interiors and architectural packages.

We have also developed a cost effective system of prefabricated modular units for use in the offshore and marine industry.

In addition to the European market, Markhus has established a presence in the Asian market through our joint venture Markhus Asia and Flexmodule Asia in Singapore.

Engineering and architectural services for offshore accommodation modules

Our companies design and fabricate adaptable systems of living quarter modules for the offshore and marine industry.

We offer complete project management packages which include documentation and technical drawings within structural, architectural and other disciplines. Our engineers and architects use AutoCAD and MicroStation CAD systems.

Prefabricated, flexible modules

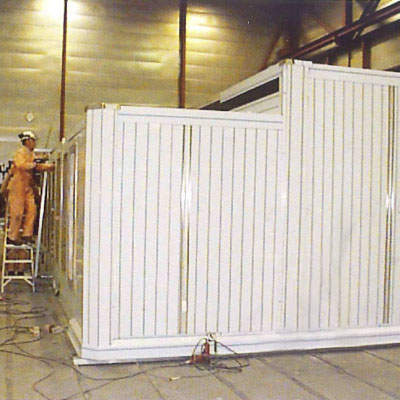

Markhus, in cooperation with Flexmodule and Carpin, are the manufacturers of the prefabricated adaptable modular building system called Flexmodule.

The super lightweight design of these prefabricated modules has been used on various projects and offshore installations for different purposes, ranging from accommodation units to control rooms and technical and utility modules.

The system is low weight and rapid hook-up, making it suitable also for extensions on existing platforms or modules where weight is a critical factor. The system is favoured by fast track construction due to its short hook-up time.

Aluminium has proved to be a safe material that is well suited to offshore modules. Advantages of aluminium compared to steel include low weight, no need for surface treatment and lower maintenance costs, which leads to minimum life cycle cost.

Specialised offshore living quarters engineering knowledge

Our engineers and architects have a speciality in the oil business, oil installations, oil platforms and floating hotels, especially different types of cabins and special solutions. This has resulted in the Flexmodule product, modules for different purposes like offices modules, multi-cabins and utility modules, but living quarters (LQ) remains the company’s core competence.

Customer reference list

Some of our satisfied customers are oil companies, drilling contractors, shipping companies and leading global providers of engineering and construction services, including:

- Agip

- Aker Kvaerner

- Amoco

- British Petroleum (BP)

- Conoco Phillips

- Dolphin

- Elf

- ESSO

- Hydro

- Keppel FELS

- Petro Canada

- Ramboll Oil & Gas

- Shell

- Statoil

- Total

- Sevan Marine

- COSCO

- SOME

- Aibel

- Master Marine

- Maracc