Twister BV is a privately held, Netherlands-based service provider that specialises in delivering the most compact and safest high-yield separation gas processing systems to the oil and gas industry.

Twister offers an inherently reliable, low-maintenance alternative to chemical-based technologies at significantly reduced costs, with solutions configured to each customer site and backed up by its position as a leading authority on fluid dynamics and separation processes.

Our company is committed to ensuring that operational benefits materialise by offering onsite commissioning services, operator training courses and post commissioning services, including real time production monitoring and operational assistance.

Cost-effective gas separation for offshore applications

Twister’s high-yield and streamlined gas separation solutions are proven to generate savings across the production lifecycle, in addition to delivering greater performance.

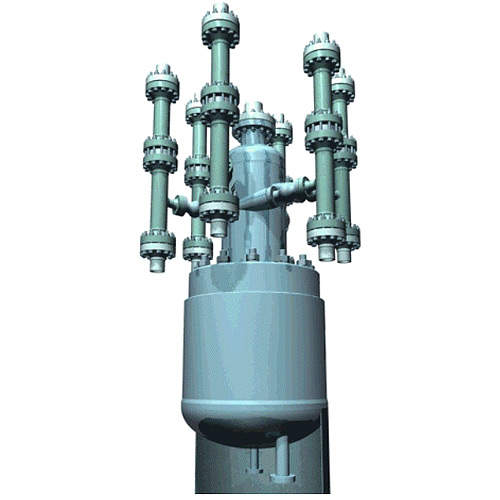

The lifecycle cost savings facilitate an increase in productivity for our clients, as well as reducing platform costs due to the system’s lower weight and minimal footprint when compared with competing products.

Twister separation processes require virtually no maintenance and are safe and easy-to-use, allowing for less stringent workplace HSE requirements than alternative methods. They also offer continuous operation and optimum natural gas liquid (NGL) recovery.

Our company’s longstanding heritage has pushed the frontier on innovation to safely and sustainably deliver economical solutions that deliver high-yield gas separation with enduring performance.

Tailored gas-processing technology for on shore or offshore environments

Our proprietary gas-processing technology is a robust, compact and profitable alternative to chemical-based solutions.

Both chemical and emissions-free, Twister systems can be started instantaneously and are flexible with no rotating parts, allowing operators to benefit from maximum output, productivity and ultimately profitability within a minimal-risk environment.

Our technology provides customer-focused solutions that meet all operators’ gas processing challenges, and are able to deliver high-quality results in both on shore or offshore environments during sour gas or sweet gas, and gas dehydration and / or dew pointing applications.

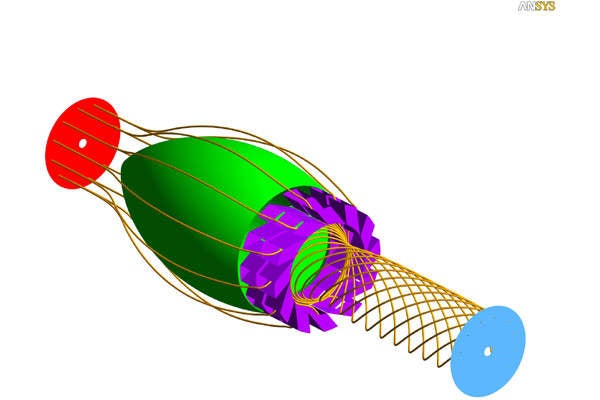

Computational fluid dynamics (CFD) expertise

Twister’s wide range of services and solutions are supported by the firm’s world-class expertise, and excellent track record in taking technologies through to commercially successful operation.

Our knowledge of computational fluid dynamics (CFD), condensation kinetics and non-equilibrium thermodynamics, as well as the individual expertise of our experienced and enthusiastic personnel, provides the perfect partnership of sustainable innovation, execution and collaboration under one well-trusted company banner.

About Twister BV

Twister systems have been operating in both onshore and offshore locations since 2004, with a competitive availability record exceeding 99%.

The integration of Twister’s simple and economical processing services has been known to contribute to net savings of up to several hundred million dollars for our clients over a ten-year period.