:max_bytes(150000):strip_icc()/GrainBinDrying-1-dfad0e37a3184c4188fcf2a1e556420a.jpg)

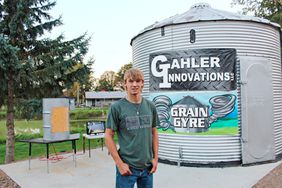

Farmers are emptying grain bins prior to planting season to make room for the next crop. The quality of the grain leaving storage depends on last year's harvest conditions and management practices.

Spoiled or out-of-condition grain doesn't flow like normal. It can stick to the sides of the bin or form a crust on the top. Workers who go into the bin to dislodge the grain can be sucked in and engulfed in less than a minute, or even faster if they break through a horizontal crust on the surface and fall into moving grain.

1. Break up grain from outside

Chip Petrea is a principal research specialist in ag safety and health at the University of Illinois. He says there's a similar hazard when grain has crusted vertically inside the bin, creating a sloping pile.

"It seems reasonable to go into the bin at the bottom to help it along because once you move some of that grain on the bottom it's likely to cascade down, but then again that's the problem," he says. "If you're in a 50,000-bushel bin and you start moving some at the bottom, then it will cascade down on you. Depending on how much is there, it could become an entrapment."

Petrea recommends breaking up crusted grain from the outside of the bin using an extendable pole with a small saw on the end designed for trimming out-of-reach tree branches. He says anytime someone is working around a grain bin, they should have another person there.

It's crucial to make sure all grain-moving equipment like augers and conveyors are off and locked before attempting to free grain, and definitely before entering a bin.

2. Don't go in without a harness

As a last resort, Petrea says, "If you decide to go in, then the recommendation is that you have a full harness and be tied off with some way to hold you in place should it start to cascade."

Megan Schossow is the outreach director for the Upper Midwest Agricultural Safety and Health Center. She also advises against going into a grain bin but seconds Petrea's recommendation to use a secured lifeline or harness if entry is necessary. It goes around the chest, shoulders, legs and groin, and is secured at two anchor points on the inside the bin.

"If someone has this harness on and they're walking around the top of, say, a crusted surface, any kind of jolting movement or jerk would basically trigger this life harness and they would stop moving," she says. "So, you would either be buried to a much less extent or you would be held above the grain."

3. A rescue tube can save lives

A person who is sucked into the grain but not completely buried is surrounded by 2,000 pounds of pressure that makes it impossible for them to wiggle out. In these cases, Schossow says a piece of equipment called a tube can save lives.

"Often times they come as two to three pieces and they get wedged around that person so that you can dig the grain out and get that pressure off of their body so that you can free them," she says.

4. Monitor air quality

Matt Surdick is the health and safety manager with CHS. He says the air quality inside the bin can also be dangerous. After sitting all winter, there could be a build-up of carbon dioxide, which you can't see or smell. He strongly advises installing air monitors to tell you what's going on.

Surdick recommends a four-gas air monitor, which tracks levels of oxygen, carbon monoxide, hydrogen sulfide, and methane. "It ensures you know what you're walking into. You can have peace of mind when you're going into that bin knowing exactly where it's at," he says. "Monitoring that space is critical."

Schossow says many people know the dangers but may not take the time to set up the safety equipment, especially if they just need to do something quick, but getting into the habit of being safe could save a life.