:max_bytes(150000):strip_icc()/235-2-bc575fb555f941e19a2bb1b082c04fc1.jpg)

These farmer ideas from across the country will extend the usefulness of farm shop features. Sponsored by Morton Buildings.

Air Supply Stations

:max_bytes(150000):strip_icc()/231-2-7b46233e1fe649a199e1efa9db4e5ead.jpg)

Beyond plumbing numerous compressed air outlets throughout their shop, Don Villwock and Jason Misiniec, of Villwock Farms in Edwardsport, Indiana, created air supply stations at three locations in the structure. The red pegboard is stocked with commonly used pneumatic attachments and tools, such as pressure gauges and inflator nozzles. For added convenience, the farming team also located a 120-volt cord storage basket with a crank retractor and 120- and 220-volt outlets at each station.

Adjustable Cutting Table

:max_bytes(150000):strip_icc()/232-2-4a7c70a40e6c460093593ff7e60a2917.jpg)

Brad Minor of Rutland, South Dakota, greatly extended the usefulness of his metal chop saw by fashioning this unique adjustable cutting table. The main arms of that table, which extend out on either side of the stand (created from a disk and 4-inch-diameter pipe), are 2-inch square tubing. Nestled inside each arm are lengths of 1½-inch square tubing pieces that will slide out to extend the length of the rack. The uprights coming off the arms are ¾-inch threaded rod whose height can be adjusted as well. The horizontal supports are 1-inch piping. "The rack is stout enough to hold most any size metal we need to cut," Minor points out. "And yet it is light enough so the entire stand can be moved away from the wall."

Outdoor Welding Area

:max_bytes(150000):strip_icc()/233-2-fee84157cdb244698eec3d6be4f33868.jpg)

To reduce welding fumes and smoke in his shop, Bill Rosener extended the roof 10 feet along one side of his shop. This created an outdoor work area where he can weld in good weather to cut down on fumes and smoke. "Plus, this provides maximum ventilation whether welding, using a torch, or grinding," the Tahlequah, Oklahoman explains. The welder is kept inside and next to the exterior door. "I equipped the welder with extra long cables to reach out to the 4x8-foot welding table so that I didn't have to move the welder outdoors," Rosener points out.

Readily Available Jig

:max_bytes(150000):strip_icc()/234-2-7e6cbb9c511e4b268b7af7888e259fe4.jpg)

When the Gerstackers at Gerstackers Farms in Midland, Michigan, poured the floor for their shop, they had the cement contractor make sure that the floor expansion joints located next to their welding area were cut at an exact 90° angle. These expansion joints, which extend out 12 feet from that 90° angle, provide a readily available jig "to assemble and then weld large panels, trailer frames, or gates," Kirk Gerstacker explains. "The jig is created by inserting short pieces of angle iron into the groove to act as standards." Gerstacker speculates that a farmer could go back in and cut such framing grooves into an existing floor. "It is crucial that those grooves form an exact 90° angle where they intersect," he warns.

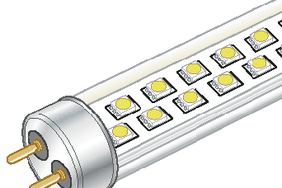

Top-Notch Cutting Table

:max_bytes(150000):strip_icc()/235-2-bc575fb555f941e19a2bb1b082c04fc1.jpg)

This super cutting table and iron rack was engineered by Lance Rezac, who farms with his brother, Tom, near Onaga, Kansas. The table and storage rack is 25 feet long so it can accommodate common 20-foot lengths of flat iron and metal rod. "The entire table top consists of rollers so we can easily position metal to be cut," Rezac explains. "At one end of the table is a rod shear, and at the other end is a plate shear." The backbone of the table and storage rack are 8-inch H-beams the Rezacs had leftover when they constructed their shop. Shelves below the table provide convenient storage of shorter pieces of metal. "The great thing about this setup is we can easily select the metal we need (which is sorted by size on the rack), lay it on the table, shear it, and then return the leftovers to storage," Rezac points out. "Large metal, angle iron, and piping are kept on a separate storage rack also located near our welding center."

Heavy-Duty Floor Anchors

:max_bytes(150000):strip_icc()/236-2-623e0a49f6ee40fea6aa683046e16893.jpg)

Variations on floor anchors abound, a testimony to this essential farm shop accessory. Mike and Hans Sulzer's take on this innovation was to bend 3-foot-long pieces of 1½-inch rod into U-shapes to create the floor anchors in use in their Monroe, Wisconsin, shop. The anchors were set in cement 3 feet deep. "The anchors' cavities are covered with a steel plate cover so we can drive over them," says Hans Sulzer. "We have used those anchors more times than I can remember bending back vehicle frames, axles, shafts, and so on."

Wider Workbench

:max_bytes(150000):strip_icc()/237-2-93c6f97c6b34408da41e2b5f02b179a4.jpg)

There never seems to be enough bench space available when farmers are working on multiple repair jobs. To create extra elbow room and better utilize the area under his storage loft, Duane Manternach built a 5-foot-wide by 16-foot-long workbench from 2x4s and 2x6s. The ends and one side of the bench are covered with building metal siding, while the other side reveals shelves that hold a wealth of tools. That bench is topped off with a laminate plastic surface that "makes cleaning the top so much easier, especially when it comes to removing oil or other lubricants," the Monticello, Iowa, farmer adds. A clean workbench provides additional room for his three boys to use the workbench for studying or work projects when Duane is in the shop. "They prefer to be out here working on that bench or in the nearby shop office," he adds. "Of course, we have a basketball hoop in the shop, so there is always a pickup game going on when their work is done."

Rolling Bench

:max_bytes(150000):strip_icc()/238-2-6dafffa651e842f7ac1bc15766ecdb9b.jpg)

Lloyd Gordon is one of the most creative farmer inventors ever featured in the pages of Successful Farming magazine. And Gordon's portable workbench reflects the Wellington, Ohioan's creativity. This rolling bench offers a wealth of tool storage provided by rod metal pegs he welded to the bench's upright storage rack. A cavity on the top of that racks holds a wide variety of lubricants, cleaners, and related aerosol products. A halogen light is mounted on top of a pipe stand fashioned so that the light's height and angle can be readily adjusted. "I have a couple of these mini-workbenches, which I can position next to long-term repair jobs," Gordon points out. "That way I'm not running back and forth to my main workbench and tool storage area for basic tools and supplies."