:max_bytes(150000):strip_icc()/7019979AATF-ba2bb1ac839c41f09535e0b031778d2c.jpg)

Illustration by Lant Elrod

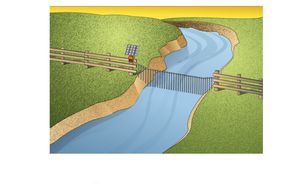

Larry Williams loads a large number of hay bales on his Texas farm. When asked why he designed, built, and patented this idea, he says: “I was getting frustrated with trying to load semis and having to push on the load. That can be hard on the bales. I decided to build a loader that made it much easier on the hay — and on my patience.”

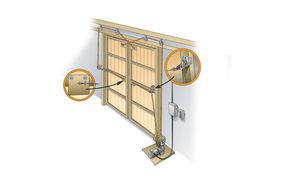

He cut both legs of his front-end loader in half, just in front of the lift cylinder pin point. Then, he fabricated two 1½-inch-thick steel plates to fit inside the rear legs’ hollow parts. To allow for a firm fit while extending and retracting the unit, he fitted nylon wear pads inside the rear legs on their tops, bottoms, and both sides. The steel plate’s front end is welded to the rear of the loader’s front section.

Hydraulic cylinders are mounted on the inside of the rear legs. One end of the cylinder is attached to the rear legs, and the other end is attached to the front section. The tractor’s factory hydraulics power the hydraulic cylinders. Pulling the lever in the cab extends the front section by 2 feet. This process can be performed while the loader is in a vertical or horizontal position.

Larry Williams

Williams operates a 10-acre Coastal Bermuda grass haying operation in Beckville, Texas. He is married to Pam, with one son, three stepchildren, and four grandchildren. Williams and his wife like to go camping in their fifth-wheel camper. Pam is a national championship clogger, and they travel the circuit: She clogs, and he helps emcee the shows.

For more information on this project, email Williams at liwilliams81@gmail.com.