:max_bytes(150000):strip_icc()/Enginestandgearbox_preview-d26e8b8cd6884b7dbaaaf4c67ec4328a.jpg)

Illustration by Lant Elrod

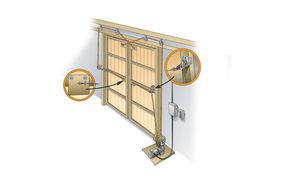

Roger Arensdorff purchased a 2,000-pound rotating engine stand from Harbor Freight, planning to rebuild an International 436 engine, which weighs about 1,400 pounds. The mounting plate did not seem stout enough to work with this size engine, so he decided to adapt to a larger plate.

He cut an 8×30-inch piece from 3⁄4-inch-thick plate steel and attached it to the existing plate. “When thinking about rotating the motor, I could see problems,” Arensdorff says. “The size and

the weight would be too much for the hand crank that came with the unit.”

He mounted a 40:1-ratio gearbox to the unit's lower frame. A 3-inch shaft, milled down for a 40-chain sprocket, was attached to the mounting plate assembly. He added a small handle on the gearbox drive and connected the chain to complete the assembly.

“I can rotate the engine with just one finger, and when I stop turning the crank, the engine stops and will not move,” he says.

Roger Arensdorff

As a graduate of Cheyenne Aero Tech, Arensdorff is a certified aero mechanic. He does mechanical work of all types but enjoys his farm mechanics above all else. He and Melissa, his wife of 32 years, love to travel; mountain hikes rate at the top of their list.

He resides in Cuba City, Wisconsin, where he produces corn and soybeans on his small farm.

For more information on this project, email him at roger-ramjet1968@yahoo.com.