:max_bytes(150000):strip_icc()/7019589shopcrane_preview-c36dd431076646aca5fcf8738bd91fde.jpg)

Illustration by Lant Elrod

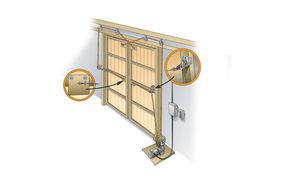

Steve Leitner of Hogeland, Montana, saw a large jib crane in a local repair shop and decided to make a smaller version to work in his own shop.

Leitner used a 6-inch irrigation pipe for the main pole, and a 6½-inch pipe for the swivel and swivel support. He made two large O-shaped plates to weld to the swivel and the support to act as large washers, which made swinging the arm much easier.

For the jib arm, he used a 6x¼x10-foot I-beam, and ½-inch cable and 3⁄8-inch plate for the cable tension and gusset. He purchased a Pittsburgh Automotive 400-pound hoist, and mounted two sets of Haul-Master push beam trolleys, connecting them with ½-inch plate steel, cut to size.

“Make sure to insert bolts at the end of the I-beam, or you may be in for a big surprise when the trolley runs off the end of the beam,” Leitner says.

Steve Leitner

Leitner graduated as a mechanic from Universal Technical Institute and serves as an EMT and service director of Blaine County Ambulance No. 2. He works predominantly as a mechanic for OV Farms. The operation includes crop and livestock production near his home in Hogeland, Montana. Leitner is a single father to 12-year-old son Colt. Colt loves working and getting involved with the ranch. Leitner loves to take photographs, especially landscapes, and has been published numerous times.

For more information on this project, email Leitner at paden3d@gmail.com.