:max_bytes(150000):strip_icc()/img_56ac1590a8b24_52109-82ee410ae40f46808dff80cb68d39185.jpg)

If one thing is clear about the Zacharias family's impressive farm shop, it is that every inch of the 125x300-foot building was designed thoughtfully. The Kathryn, North Dakota, shop happens to be the first Morton hybrid building erected.

"With many metal buildings, we would've had to deal with posts in the inside," said Vance, the eldest of the Zacharias sons. "We wanted a clear span so we could work with whatever width of equipment in whatever manner we wanted."

Space for Every Shop Need

The shop's massive interior is split into three areas: 40 feet of storage for tools and parts, 105 feet of maintenance space, and 115 feet for truck parking. Three 42-foot doors are spread out across the shop's southern sidewall and a 32-foot door on the opposing sidewall allows machinery to pass through.

:max_bytes(150000):strip_icc()/zachabove1-8fcc7a33ed2f4649b1f0a863870692ca.jpg)

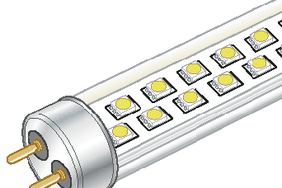

The remaining 40 feet make up a completely separate wash bay. The space has two 28-foot overhead hydraulic doors to allow for passing through after washing is complete. Clever side lighting makes the wash bay the best place to clean up equipment. Waterproof T-8s are mounted on the area's sidewalls to get a perfect display of the sides and bottom of machinery.

"Theoretically, you don't care about the top of what you wash," said Vance. "The sides are what you see."

Keeping Things Clean

In the maintenance area, a large stretch of road fabric is used as a floor mat. It was originally a temporary floor cover, but the family really liked the difference the fabric made.

"It reduces the amount of scuffing on the floor, prevents falling wrenches from denting or cracking the concrete, absorbs oil to some extent, and lessens issues an individual can have when standing on concrete all day," Vance said of the floor mat.

When picking a location for the shop, the family chose an area far from the farm's corn dryer to avoid dragging in the mess. To easily clean the floor of the shop, the family invested in a factory floor sweeper. It kicks up a minimal amount of dust and makes the task of sweeping the huge shop a lot less daunting.

Structure Details

:max_bytes(150000):strip_icc()/zachwash1-ff4ee81cccb54ac581d9199b5da09a29.jpg)

To accommodate future farm equipment that seems to be getting taller, the shop sidewalls are 21 feet tall. Inside the building, the roof raises up 12 feet at its center peak. This helps with ventilation and provides plenty of extra space for clearance.

"The building is actually very economical to heat throughout the winter; it only costs us about $45 per day with off-peak heating," Vance said. The building has in-floor heating with heating lines every 12 inches. In total, there are 7 miles of tubing throughout the entire building. As for the walls, they have R-30 insulation and are wood with metal rafters. The roof has 14 inches of blown-in insulation.

Vance said the walls were painted for aesthetic appeal, but starting at 10 feet above the ground, the walls are made of acoustical steel to dampen noise issues.

Before pouring the floor, the family laid down air lines to two different locations within the shop. Both are permanent air reels that have hoses capable of reaching out across the shop to meet their needs.