:max_bytes(150000):strip_icc()/Double20drop20low20boy20tri20axle20trailer20illustration-2-2000-c41eb33a5e994eaba9bffc74116b58af.jpg)

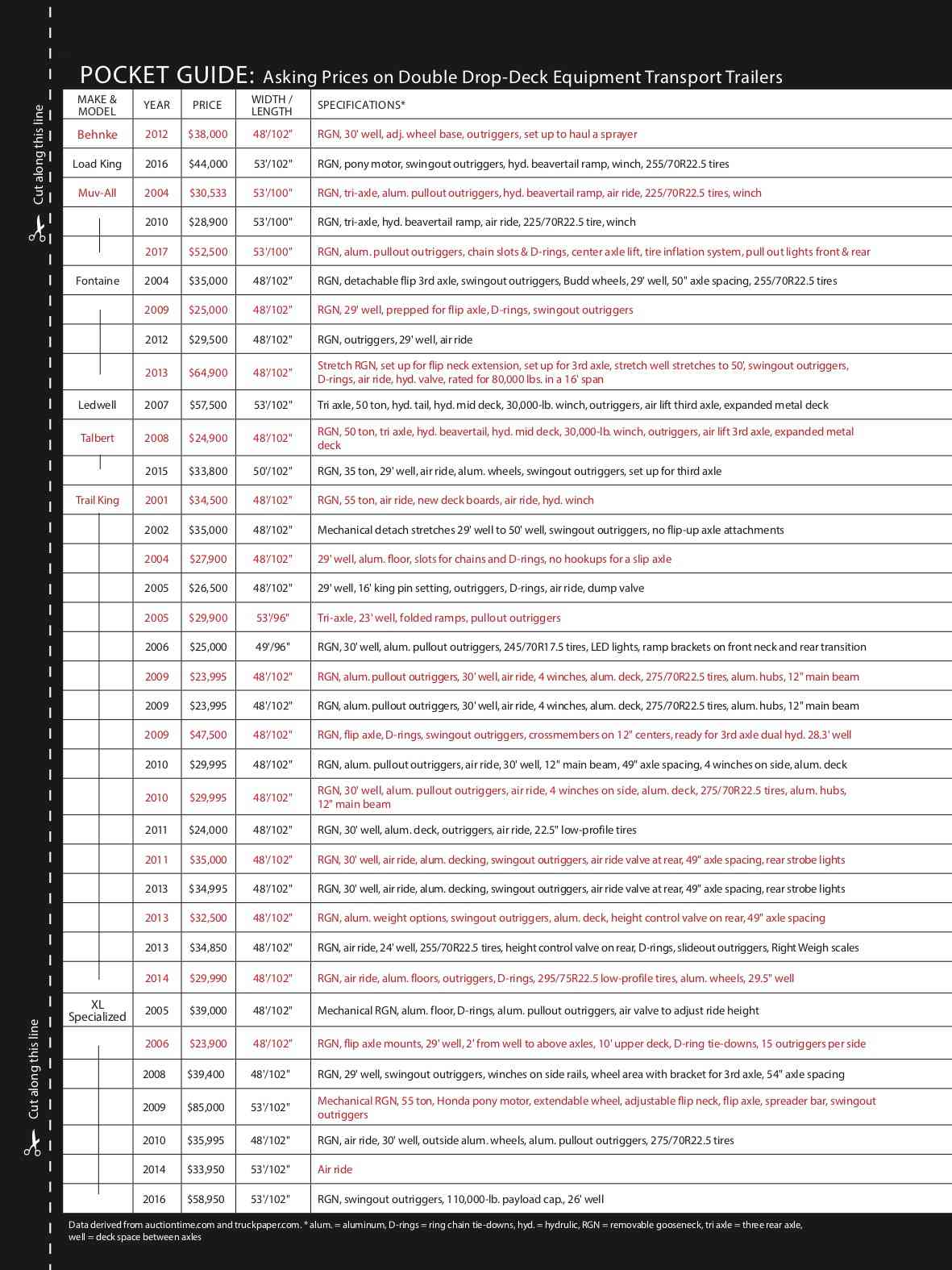

In the wide world of transport trailers, the king of the hill – in size, capacity, and certainly cost – is the equipment transport lowboy trailer. These double drop-deck designs are becoming more sought after as the geographic areas of farms increases. Double drop-decks with outrigger brackets have become popular for transporting sprayers and spray supplies.

There are other trailer configurations available varying by configuration, length, width, and deck height. Following are the three basic trailer types on the market.

- Flatbed trailer: The workhorse of the open road, simple flatbed trailers vary in length from 45 to 60 feet; their decks spread out 96 or 102 inches wide, and they sit 4 feet, 8 inches off the ground. These trailers are rated to accommodate weights of up to 48,000 pounds, 65,000 pounds, or 96,000 pounds, depending on the design. An exception to this: Stretch versions of flatbeds (also called trombone trailers), are 48 to 80 feet long so they can legally carry over-length items. These stretch beds have a lower maximum weight rating, however, of 45,000 pounds. Flatbed construction (primarily their frames) utilize either steel, aluminum, or a combination of both metals.

- Drop-deck trailer: Often referred to as stepdeck trailers, these units feature a gooseneck hitch upper deck that is usually 10 to 11 feet long. The trailer's main deck, or well, is 37 to 38 feet long riding 39 or 40 inches off the ground. Deck widths are 96 or 102 inches wide. Drop-deck construction is heavier than flatbed design and, as such, can transport loads from 44,000 to 45,000 pounds. Stretch versions of drop-deck trailers extend to 76 feet.

- Double drop-deck trailer: Often called lowboy trailers, the well of this trailer's center deck dips below the trailer's front and rear trailer axles. This lowers the center deck's height to between 15 and 18 inches off the ground. Generally between 48 and 53 feet long and 96 or 102 inches wide (a wider version of the trailed, called a "9 wide," is 108 inches wide), double drop-decks are constructed of high-strength steel capable of hauling loads in excess of 55,000 pounds. Yet, the common weight limit of the trailer is 40,000 pounds. Double drop-decks are feature-rich. Many of them are equipped with removable gooseneck (RGN) front decks, which allows equipment to be driven onto the front of the trailer. Also common on ag transports are various forms of outrigger brackets that are installed or swing out to accommodate planking that extend their width carrying capacity. Another option are flip axles consisting of a third axle that is flipped up and laid on the deck when not in use or moved down and locked into place. And then there are slide-axle designs that allow the rear axles on the trailer to move forward lowering the trailer's rear deck to the ground for loading.

Do Strong Commodity Prices Mean Higher Machinery Values?

Things were looking pretty good for the American farmer at the tail end of 2020.

Whether you needed it or not, there was a healthy injection of government payments, and tighter stocks-to-use ratios gave commodities a late boost assisted by poor growing conditions in South America and rising foreign demand. This increase in income drove more farmers to seek out equipment purchases to help ease the pain of year-end taxes.

We compared December 2020 combine sales in the Tractor Zoom (TractorZoom.com) database in 2020 with the two previous years' final month. The reason we focused just on December is to limit the variability that certainly happens with low-volume sales months. For instance, 2020 finished on a vastly different note than 2018 and 2019 for farmers, which makes for interesting comparisons. Does this positive change in farmer sentiment have an impact on machinery values at auction?

The short answer: Yes.

The long answer: It is complicated.

When we plot the price of all combines that sold for over $10,000 (to ignore those combines sold for scrap), we get a cluttered mess, yet a couple points are clear. There appears to be more 2020 low-hour harvesters sold at a premium price above 2018 and 2019. The other insight happens around high-use machines, where we do not see 2020 values above the prior two years.

Based on my experience on the farm, and in talks with dealers across the country, there is a different mentality that many farmers have when approaching low-hour machines vs. high-hour. It's hard to exactly distinguish where that point is, but on this graph, it appears to be around 2,000 to 2,500 hours. In equipment above these hours, the values drop and there is more parity. This 2,500-hour mark is where we make our break.

Filtering this data down to less than 2,500 hours (see the table below left) proves that 2020 is outpacing the two previous years. On average, 2020 prices are about 5% above 2019 and over 30% above 2018. This 30% premium is especially significant when you consider the average amount of hours on these 2018 combines was 5% greater. In December 2018 this set of low-hour harvesters only brought $56 per machine hour and in 2019 and 2020 farmers were paying an average of $79 to $80 per hour.

When we shift to the older end of the field (as seen in the tables below and to the right) we discover that the same price premium did not carry over in 2020 – 2018's high-hour prices average 7% higher than 2019, and almost 9% above 2020 values.

While the value difference is tighter than the lower hour combines, the cause for this flip is counterintuitive. At the least, it is worthy of a debate when your morning coffee group gathers again. At the most, this twist could cost you thousands of dollars if you are unaware. It pays to research current comp values in a volatile market.

| Year | Category | Avg Hours | Avg Price |

| 2018 | Combines | 1,774 | $100,245 |

| 2019 | Combines | 1,588 | $126,737 |

| 2020 | Combines | 1,685 | $133,750 |

| Total | $1,672 | $125,447 |

| Year | Category | Avg Hours | Avg Price |

| 2018 | Combines | 3,782 | $43,942 |

| 2019 | Combines | 3,603 | $40,963 |

| 2020 | Combines | 3,610 | $39,247 |

| Total | 3,657 | $40,898 |