:max_bytes(150000):strip_icc()/farm-hacks-27cc20ef6ca040588c82d8e7ff3d209d.jpg)

Rapid and Right-Angle Screwdriver

Do you lack the tool to remove screws in an inaccessible location? Do you need to make quick work of removing stubborn screws without stripping out their heads (when using an electric drill)? The solution here is to use a ¼-inch socket to hold a hex-end driver bit. You'll need to employ the socket reducer in your set to pair that small a socket to your ratchet. In use, press down on the ratchet head with your hand to provide sure contact with the screw head.

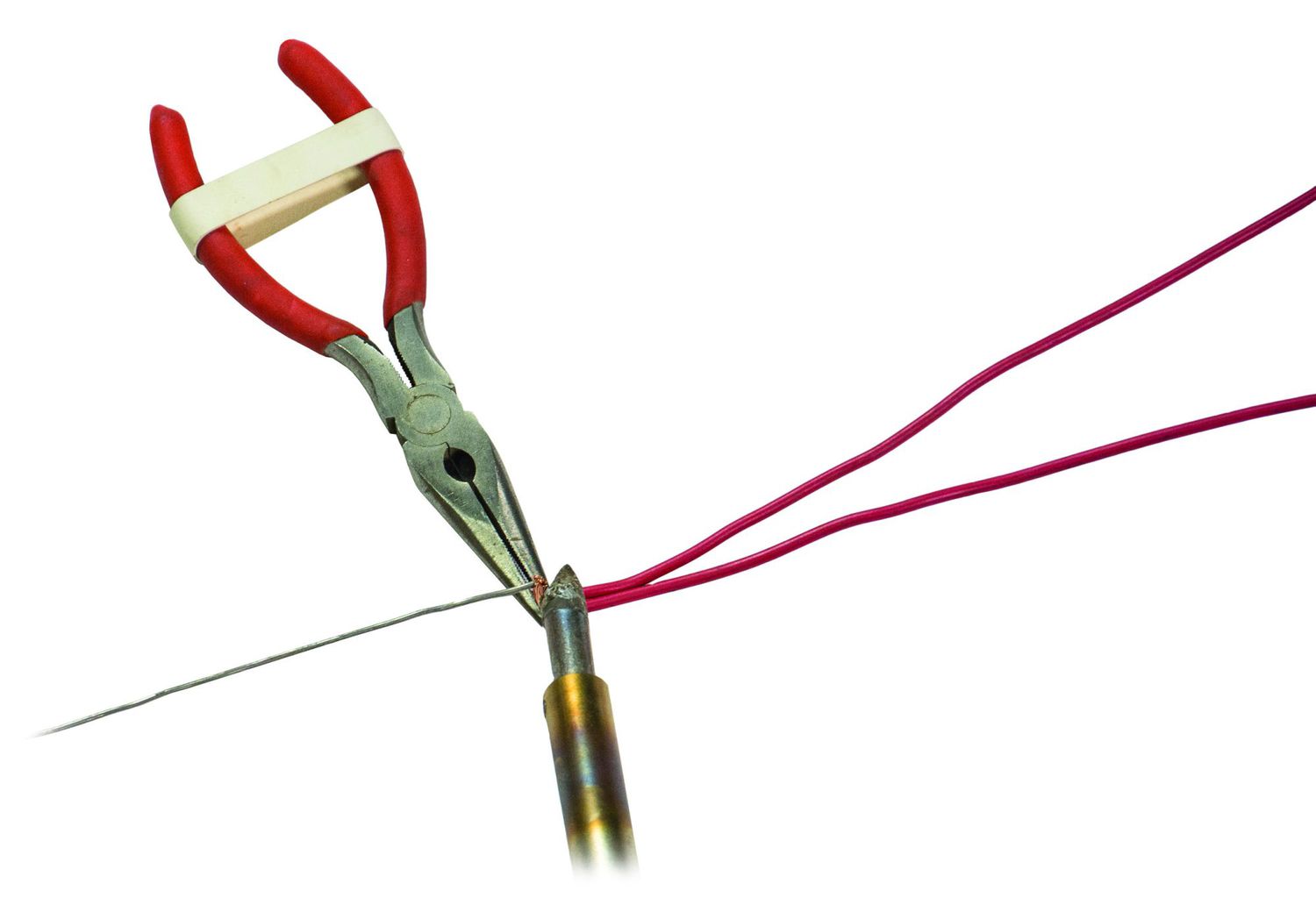

Ready Soldering Clamp

Some fine wire connections require soldering to provide a solid connection. The frustration with this chore is holding the two ends of the wire together and upright while, at the same time, applying a soldering iron and solder wire. Create a make-do soldering hemostat with a pair of needle-nose pliers and a rubber band as shown. You could use a locking needle-nose pliers, but the locking mechanism can crush the wire coating, which would create a potential short.

Ready Wrench Extension

Are you in need of extra reach to remove a bolt or nut hiding in a hard-to-reach location but you lack an extra-long boxed end wrench or ratchet wrench handle for the job?

A quick solution is to combine two wrenches to create a tool extension. The trick here is to loop the boxed end of the first wrench through the open end of the second tool so they "lock" together. This tool trick has the extra benefit of giving you more leverage to remove stubborn fasteners.

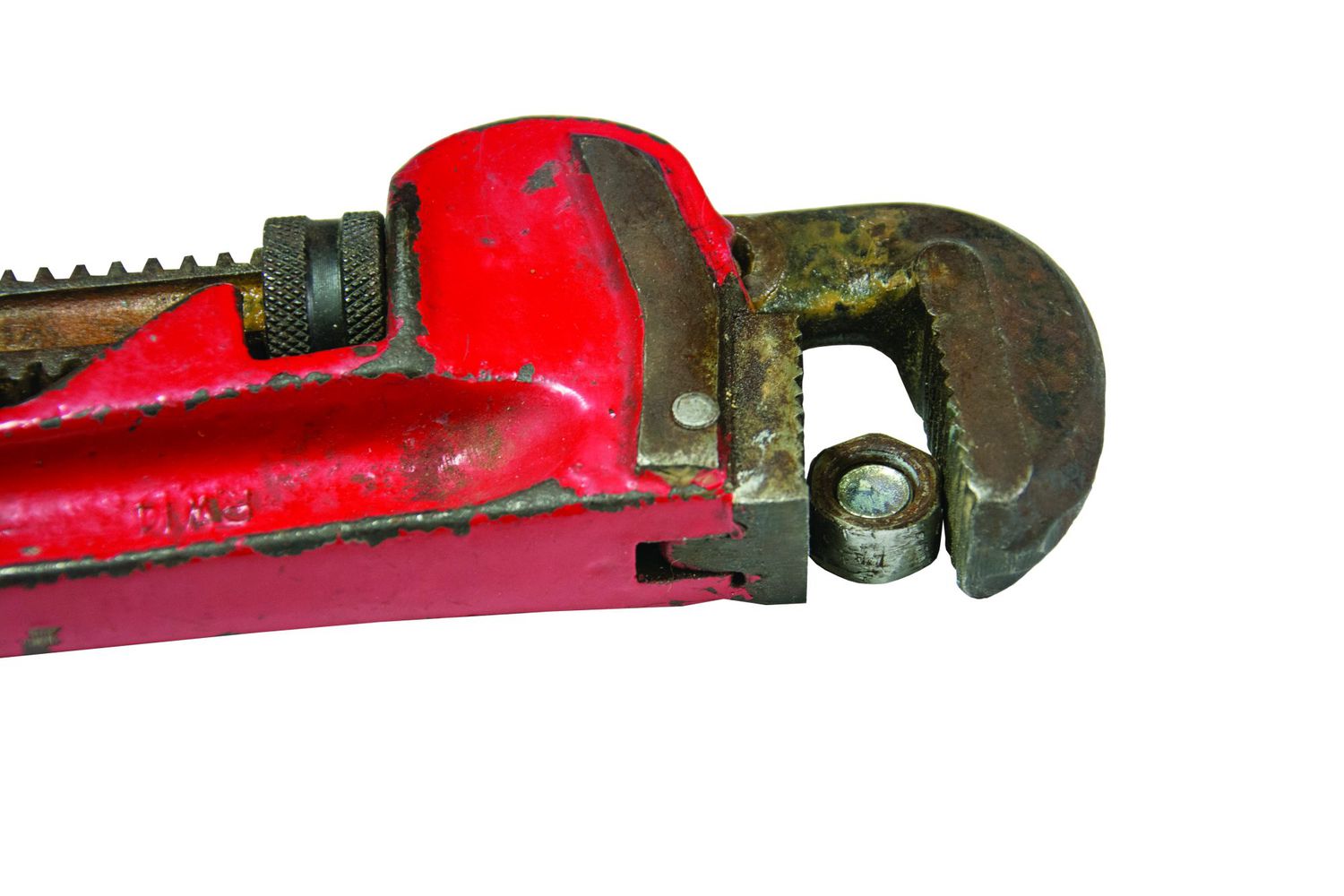

Pipe Wrench to the Rescue

Rounded-off nuts or bolt heads can prove a huge challenge to remove even with the use of a locking pliers, which can spin round the nut when extra leverage is applied.

The quick-fix solution is a pipe wrench. Not only are the teeth on a pipe wrench more aggressive than a locking wrench (thus biting deeper into the nut or bolt head) but also the locking action of the bottom jaw forces those teeth into the fastener for a sure hold. An added plus is that the pipe wrench handle is longer to provide more leverage.

Watch these mechanic make-dos in action in this video: