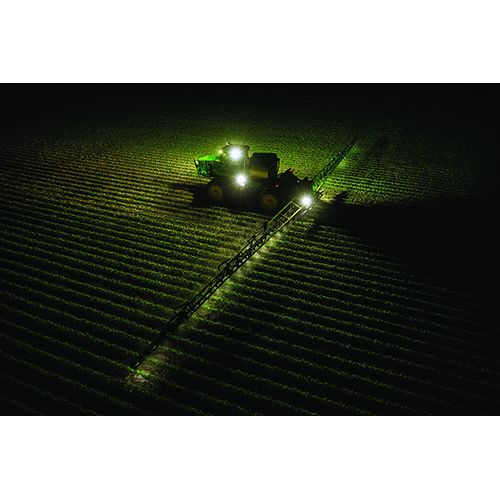

Meeting the application needs of today's farmers means enhancing operator comfort, offering high-quality application, and providing as much machine uptime as possible. With the introduction of five new sprayers in its 400 and 600 Series, John Deere is checking all of those boxes.

"Each sprayer features a new, larger cab with your choice of three comfort and convenience packages available to fit a variety of needs," says Joel Basinger, marketing manager for John Deere. "The 400 and 600 Series sprayers turn technology into application quality and enhance machine uptime for customers."

All-day comfort combined with exceptional visibility is the focus of the new cab. Farmers can choose from three comfort and convenience packages, which also include new lighting options. The Ultimate package features a heated, ventilated leather seat that swivels up to 24 degrees to the left or right and has an ActiveSeat II suspension. The package also includes a 6.5-inch touchscreen satellite- and smartphone-ready radio, five USB ports, a 12-volt outlet, footrests, refrigerator, and dual-tilt steering column with a leather-wrapped steering wheel. An optional Category IV filtration system streams continuously filtered air into the cab to help keep the operator's station clean.

Options for better visibility include electrically adjustable and heated mirrors, additional cameras, and LED lighting packages.

To keep the sprayer in the row, allow for increased spraying speed, and to reduce operator fatigue, John Deere AutoTrac, RowSense, and AutoTrac Vision are also available. The ISO Auxiliary Mapping enables third-party guidance monitoring.

By employing the John Deere ExactApply option, operators can control droplet size, spray pressure, and individual nozzles on the sprayers. Further enhance spraying accuracy by maintaining the boom's position with the optional BoomTrac Pro 2.

"With BoomTrac Pro 2, we're seeing 22% more accuracy," Basinger says.

Basinger says the optional pressure recirculation and system air purge technology also improve job quality and simplify cleanout while reducing product waste.

"Boom pressure recirculation circulates the chemical throughout the entire boom and solution system. That way, when an operator is loading the chemical on the sprayer, it's all in the proper concentration out on the boom when he starts spraying, eliminating concerns of over or under applying," he explains. "Once spraying is done, the air purge technology lets you blows air through the system, pushing any chemical out on the boom back into the tank, so you can save it for another day's spraying."

All 400 and 600 Series sprayers are built with a John Deere PowerTech Engine and the CommandDrive powertrain that transfers power evenly to all four wheels when needed. Operators can confidently spray over large hills, knowing CommandDrive automatically increases engine RPM when more power is needed to maintain a consistent speed and spray pattern. On flat terrain, Auto Mode maintains the selected ground speed and application rate at lower RPM, reducing fuel and DEF consumption.

Technology = Uptime

When it comes to the 400 and 600 Series sprayers, technology means uptime. Each sprayer is equipped with a JDLink connection, an integrated StarFire 6000 GPS receiver, Generation 4 CommandCenter display, and AutoTrac guidance.

"Instead of making an operator choose among the different technology options, John Deere is really trying to integrate them into a machine, so it's more seamless," Basinger says. "These sprayers come standard with the integrated technology a farmer needs to reduce overlap and maximize inputs."

Once activated, JDLink will stream machine and field data to the John Deere Operations Center so a farmer can easily monitor and track job quality, machine location, and machine hours from anywhere. In addition, he can setup prescriptions for individual fields within the Operations Center and push that information to the Generation 4 display in the cab.

Also in the Operations Center, the Analyze tools enable a farmer to review field data, compare target rates with actual-applied rates, and adjust plans as needed. If you opt to share your data with a trusted advisor, the Operations Centers allows a farmer to accomplish that easily and securely.

In addition, the AgLogic app can be used to submit application jobs from the cab of the sprayer and to keep accurate records of what work was done in each field.

"Not only can these sprayers stream machine and field data to the Operations Center, but with the owner's permission they can send machine health information to the owner's John Deere dealer," Basinger says. "That enables John Deere Connected Support – where the dealer can remotely monitor the machine for any sign of trouble and fix the issue before it causes downtime, thus maximizing the sprayer's uptime."

Diagnostic capabilities have also been improved for the farmer. "When a trouble code pops up on a farmer's display, he will actually be guided through the diagnostic steps, which includes descriptive text, so he can try to solve the problem himself," Basinger says. "If a farmer does need to call his John Deere dealer, the technician can walk him through the steps using live remote access. It's really about trying to get them up and running again as quickly and as efficiently as possible."

There are three models available in the 400 Series.

* 408R includes an 800-gallon tank and a 280-hp PowerTech 6.8 L engine with a maximum field speed of up to 20 mph, and transport speed of up to 30 mph.

* 410R is equipped with a 1,000-gallon tank and a 310-hp PowerTech 9.0 L engine.

* 412R comes with a 1,200-gallon tank and is powered by a 326-hp PowerTech 9.0 L engine.

Both the 410R and 412R can reach field speeds of up to 25 mph and transport up to 35 mph.

There are two models in the 600 Series.

* 612R features a 1,200-gallon tank and a 355-hp PowerTech 9.0 L engine.

* 616R is equipped with a 1,600-gallon tank and a 375-hp PowerTech engine.

Both sprayers can reach field speeds of up to 25 mph and transport up to 35 mph. All five of the sprayers in both series can be equipped with 90-, 100-, or 120-foot steel booms, or 120- or 132-foot carbon-fiber spray booms.

Dry Spinner Applicators

There are also two dry spinner applicators, the 400R and 600R. The 400R is equipped with a 200-cubic foot dry box and a 326-hp PowerTech 9.0 liter engine. The 600R comes with a 200- or 300-cubic food dry box and a 375-hp PowerTech 9.0 liter engine. Both offer the integrated StarFire receiver, Generation 4 display, and JDLink connection, as well as the same cab and lighting packages as the sprayers.

John Deere 400 and 600 Series sprayers will be available to order in June 2021. For more information, visit your local John Deere dealer or JohnDeere.com.