:max_bytes(150000):strip_icc()/IMG_1049-2000-26d700e57d544121bb4da1490b89ce84.jpg)

With a combination of inventive minds and a careful planning process, a unique, customized 50×120-foot shop was crafted by Paul and Craig Heineman just outside of Ogden, Iowa.

When the brothers were looking to build the necessary shop for their growing operation, efficiency was at the top of their list. "Necessity is the mother of invention. If you don't have what you need, if it's not feasible, or if it's too expensive, then you try to fabricate something yourself," says Paul Heineman. "That's just the way we look at it."

The frame of the shop is built from salvaged metal off a gas station awning that was taken down. The large posts that hold the canopy over gas pumps at convenience stores are incorporated into Heineman's shop as the pillars on the sides, allowing the structure to reach 21 feet tall. This made the shop taller than it was originally, giving the Heinemans more space to work on large equipment. However, that was just the beginning of the brothers' inventiveness.

Service Pit

One of the most unique features built by the Heinemans is the hydraulic service pit engineered by Paul. The pit is constructed with two I-beams and a scissor lift underneath to raise and lower the lift, which runs on a small hydraulic cylinder and electrical hydraulic pump. The two foot controls (one up and one down) are engineered from starter switches.

Heineman's service pit makes oil changes simple and hassle-free. A used oil receptacle is lowered in the pit, rolled under the piece of equipment to change the oil, then rolled back out, and raised for disposal without mess.

Oil Center

An oil center located in its own smaller room next to the sidewall door is equipped with five reels hooked together with air pumps. The reels are able to reach the nearby pit for complete oil changes on equipment and vehicles. The bulk oil storage sits on top of the center out of the way.

"Oil areas tend to grow and expand, and pretty soon you're tripping over buckets. Being able to close it off keeps the area cleaner and tidier," says Paul.

Abundance of Air

One-inch steel pipe runs in a loop around the 120-foot structure with outlets coming down every post. The loop allows for equal distribution of air acting as a reservoir, allowing more capacity to the ends of the lines. The shop also maintains a rolling cart with an air reel for easy accessibility.

Office and Break Room

Another 30×30-foot lean-to is attached to the shop where the office and break room are.

The break room holds a piece of the Heinemans' heritage. "We had a barn falling down, so we cut the top of the front part of the barn off and put it inside the break room," says Paul. Before building the shop, numerous cedar and maple trees were taken down, cut up, and dried, and then installed as part of the office walls. Cold storage sits above the two rooms.

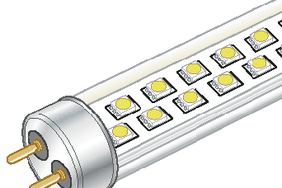

Power Switches

Before designing the shop, the Heinemans ran the electrical plastic conduit under the floor to save on the amount of usage around the 120-foot structure. Three-phase power runs throughout the shop, allowing them to work on larger motors, multiple projects, and fabricating equipment. The lights can be programmed to turn off certain features in the shop. From the air compressor to the ceiling fans, everything in the shop can be turned off or on with the push of a few buttons.

Ideas for the Future

The Heinemans are always looking for new opportunities and aren't finished yet with their shop. "When we designed the shop, we had the idea for two, 2-ton trolley cranes. So within the foundation there's spread footing over each of the pillars to handle the weight," says Paul.

The Heinemans believe in a need basis for the future. If the need arises for a new feature, it might be engineered into the shop.

"We used to work out in the dirt when the old shop became too small and had to do everything outside depending on the weather," says Paul. "So when you can get your equipment inside in the wintertime, it makes things easier to work on and everyone is happier."