:max_bytes(150000):strip_icc()/102804340-2-2000-b02c71a6afc74fcd9953d48586bf5843.jpg)

While videotaping an older shop for the Successful Farming Show on RFD-TV, I was asked by its owner, John Kingma, if he ought to upgrade the lighting in the structure. Turns out, he had been in other shops wired with T5 fluorescent lights and was impressed with the bright illumination. "My lights are older fluorescents. I'm being told I may not be able to get replacement tubes for them in the future," the DeMotte, Indiana, farmer says, pointing to his shop's ceiling.

So in order to help him and to satisfy my curiosity, I set out to discover what could be done to upgrade older shop and shed lighting. A day into my research, I was seriously confused and certainly frustrated. That's because the world of lighting has become very diversified with various designs and grades of linear fluorescent lamp (LFL), compact fluorescent lamp (CFL), and light-emitting diode (LED) products.

Even more confounding is the fact that we still think in terms of watts alone when rating lighting. True, watts consumed generally determine the brightness of a bulb. With today's LFL, CFL, and LED bulbs, light color (rated in Kelvins, or K) and design also has a huge impact on illumination.

Confusing the issue even further is the fact that manufac-turers are prone to post incandescent bulb wattage equivalents on their lights. Turns out, these ratings are often arbitrarily set by the manufacturer. This explains why I was disappointed when I bought a CFL bulb rated to replace a 100-watt incandescent that ended up burning more like a 60-watt bulb.

What's With Lumens?

The true gauge of a bulb's worth is measured in lumens, which is a description of the ambient light coming from a bulb. Lumen output is printed either on the bulb itself or on its packaging. So, when upgrading lighting in a building, first determine the amount of light (described as lumens) needed to illuminate an area. Start this process by multiplying the length and width of the area being lighted. Next, multiply that area by the following recommended lumen-per-square-foot guidelines from the Department of Energy.

AREA TO BE LIGHTED LUMENS NEEDED PER SQUARE FOOT

Machinery Storage............................1,500-1,750 lumens

Mechanical Workshop.......................2,000-2,500 lumens

Office.................................................3,000 lumens

Detailed Mechanical Work.................4,000-5,000 lumens

(e.g., over a workbench)

Utilize the lumen rating of a fixture or a replacement bulb to determine what supplies to purchase for an upgrade. Lumens, not watts, are the true rating of a bulb's ability to produce light.

Some Bulbs Are Dinosaurs

The discontinuation of a wide variety of bulbs is going to have a impact on a shop's lighting in the future, forcing upgrades of existing light fixtures. In that regard:

- Incandescent bulbs of all wattages will no longer be made in the U.S. as of December 31, 2016.

- T12 linear fluorescent bulb and ballast (LFL) manufacturing stopped in 2012.

- 700 series T8 bulbs were phased out in 2014, replaced with 800 and 900 series T8 lamps.

You can still get replacement bulbs for these lights, due to imports. The days of incandescent, T12, and 700 series T8 bulbs being stocked in stores is fast waning, however. Also, the future of 800 and 900 series T8 bulbs is in question.

And for good reason. All of these light types are inefficient, short-lived, and lighting lightweights, as the comparison table on the next page illustrates. So if your shop or storage shed is wired with these products, upgrading lighting in the future will be a necessity. The benefits of doing so will be lower electrical usage and improved illumination.

The task of upgrading screw-in, socket-type bulbs is simple. Go with CFL or LED bulbs, either of which work in existing incandescent sockets. For now, CFLs are the cheapest of the two lighting types. The price of screw-in LED bulbs is dropping, though, as manufacturing numbers increase.

The same is also true of old metal halide (MH) and high-pressure sodium (HPS) lamps that need upgrading. If those fixtures are in good condition, LED retrofit kits are available to replace these bulbs. Unfortunately, CFL lights will not work in MH and HPS fixtures.

Upgrading Tubes Is More Complicated

The biggest challenge with a shop lighting improvement involves replacing linear (tube) fixtures. In that regard, you can employ two strategies:

- Change all fixtures with T5 or LED fixtures.

- Keep the old fixtures and retrofit them to accept LED tubes.

Due to the rapidly expanding offering of LED bulbs, you can switch to LED lighting using old T12 or T8 fixtures.

That is not the case with T5 fluorescent bulbs, which will not work in either T12 or T8 fixtures. True, older fixtures could be retrofitted with new tombstone sockets to accommodate T5 bulbs. However, you'll also need to replace the fixture's ballast to drive those T5 bulbs.

T12 and T8 fixtures employ ballasts and sockets that won't accept T5 bulbs. T12 fixtures use magnetic ballasts, and T5s run with electronic ballasts. T8 fixtures use electronic ballasts, but the ballast a T5 bulb requires is tuned to its needs. Finally, the prong spacing on T5 bulbs is narrower than T12 or T8 sockets spacing.

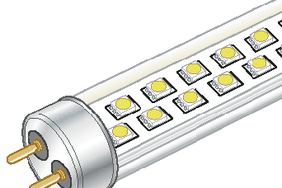

On the other hand, there is a variety of options for converting fluorescent fixtures to LED bulbs. Such bulbs don't require a ballast to operate. So the ballast can be removed from the fixture entirely. A T12 or T8 conversion to an LED bulb may also require new sockets. But that depends on the original fixture.

There are a number of videos online that show this conversion process. Find one of the better videos at youtube.com/watch?v=CRZdN5KtG8k.

When opting for LEDs, avoid purchases based on price alone, warns Charlie Szoradi of Independent LED (independentled.com).

"All tubes are not created equal," he warns. "Look for LED tube manufacturers that are ISO 9001:2008 certified. Ask for source documentation and third-party testing data. Also, look into LED tubes that are made domestically or that meet the International Class A-10 LED Tube Standards."

Finally, check with your local utility to see if it offers rebates for converting to LED lights. In some cases, as much as 60% or more of the cost of upgrading is covered by these programs.

:max_bytes(150000):strip_icc()/Screen20Shot202016-10-2720at205.01.3620PM-2-fed5622331e4425fb50ab48ff4a1eade.png)