:max_bytes(150000):strip_icc()/2023-04-04_14-40-42-2-f4954b819a1f4a018f314fd149bd6b7e.jpg)

It's believed that ancient Egyptians invented the first scale in about 3100 B.C. Because they did not yet use coins for trading goods, they assigned values by weight to different types of metals, including gold, silver, and copper. Ironically, a large set of scales in Texas is still used to determine the value of a precious commodity — water.

While producers have several ways to measure rainfall and irrigation applied to a field, the Bushland USDA/ARS Conservation and Production Research Laboratory in Bushland, Texas, literally has a scale to weigh not only rainfall and irrigation, but also all components of the water balance, including deep percolation and crop water use, or evapotranspiration (ET).

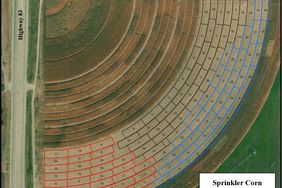

In fact, the laboratory has four of the devices, formally known as large weigh-ing lysimeters. Each lysimeter contains an undisturbed block of soil that measures about 10×10 feet at the surface and is 7½ feet deep. The lysimeters are positioned on scale platforms equipped with load cells, all housed within accessible underground enclosures. Two are located in the center of fields irrigated by a lateral move sprinkler system, while the other two are irrigated by a subsurface drip irrigation (SDI) system.

Measure All Moisture

Those lysimeters allow the research team to directly and accurately measure crop water use (or ET), something that's not possible with other methods, explains Gary Marek, research agricultural engineer with the laboratory. Crop growth and yield data collected from the lysimeters and surrounding fields are used with seasonal ET to determine crop water productivities of sprinkler and SDI systems for regional crops.

"As well capacities decline, we need to be thinking about what limited irrigation is going to look like in terms of irrigation systems and management," Marek says. "However, in the research setting, we still often irrigate for maximum yield, which means we're supplying as much water as the crop can use, called 'full' irrigation.

"We do this even though some groundwater districts have already limited irrigation to around 18 inches of water or less annually," he continues. "That's because we're trying to determine unstressed crop yield potential and associated crop coefficients that can be scaled down for producers with limited well capacities. To understand what the crop yield result of that scaling down could be, we often include a 'deficit' irrigation. Since the lysimeters were installed in the late 1980s, the research team has gone from high-pressure systems with overhead impact sprinklers to low-pressure sprinkler systems and subsurface drip irrigation."

Low-pressure sprinkler packages have included mid-elevation spray application (MESA), with drops positioned about 5 feet above the ground surface, and low-elevation sprinkler application (LESA) with nozzles about 18 inches above the ground. The lab also went from comparing dryland fields to irrigated fields to evaluating overhead irrigation with SDI in 2013.

:max_bytes(150000):strip_icc()/A20second20irrigation20lysimeter20plot_preview-2-91e056764ba840ea830ebcce5a76a7ad.jpg)

"We try to include at least three years of measurements for a particular crop in any of our crop coefficient studies to capture the year-to-year variation in weather conditions," he says. "Unfortunately, there can be a perceived disconnect between what we're doing and what producers with limited well capacities are doing, since we're trying to determine the upper limits of crop production. However, we continue to learn things that can help all producers irrigate more efficiently, including those who are limited on water."

Yield Not Proportional to Water Applied

Grain production isn't proportional to water reductions. "We know, for example, that corn can require as much as 30 to 34 inches of water to attain a 250- to 300-bushel-per-acre yield, with irrigation being a portion of that, depending on rainfall," he says. "However, we've also shown that if we reduced the amount of water applied by 25% with our deficit irrigation, based on the full amount the crop will use, we only saw about a 15% reduction in yield. So that's kind of been the target for a lot of guys with limited well capacities."

Corn has typically provided the greatest return on investment, but it also requires large input costs, Marek adds. "As those costs increase, we have to look at the balance and figure out where we see the greatest efficiency."

Subsurface drip irrigation is more efficient. "It varies by year and crop, but overall, we're seeing a reduction of around 13% to 15% with subsurface drip irrigation com-pared to the sprinklers using LESA nozzles, with the same or better yields for SDI. There have been some years when we've used up to 6 inches less of water with drip compared with the sprinkler," he says.

On the other hand, SDI tends to require a lot more management, he notes. In addition to maintaining sand filtration and back-flushing systems, producers must monitor for leaks in the tubing. Subsurface leaks are difficult to find once the crop has emerged, and the practice makes it difficult to water in dry fertilizer and to help with seed germination in a dry year. "It's difficult to promote germination with a subsurface drip system," Marek admits.

"It can take a lot of irrigation to push water to the surface," he says. "Our deep, heavy soils can hold most of that extra water, and we have seen the crop use it during the rest of the season. Folks with sandy soils would not be so fortunate. Having to do that, or missing leaks that occur, can offset water savings you would otherwise realize with drip irrigation."

Cotton requires less water than corn. "Considering the water savings cotton offers and the availability of new genetics, it's not surprising that we're seeing cotton migrate north as an alternative crop to corn," Marek notes. "According to our field studies, you can grow cotton using roughly 60% of the water needed for fully irrigated corn. In fact, in 2019, we grew three-bale cotton per acre on just under 20 inches of total water, including rainfall, irrigation, and soil water. Unlike corn, which often yields more with increased irrigation, cotton tends to produce more vegetation with fewer bolls if it is overwatered."

Niche Markets Can Cut Irrigation Water Use

Sometimes, it's the niche market that provides an unexpected opportunity to reduce irrigation. "The grain corn requirements of beef feedlots have resulted in the region being in a corn deficit, requiring corn to be railed in from the Midwest," he says. "However, in recent years, we've seen an influx of dairies to south Texas and other states, creating a need for forage crops.

"Corn silage is expensive to haul. That, of course, has created a localized market for corn silage for some producers located near dairies," Marek continues. "Some producers are growing it on contract and concentrate their water allotment on fewer acres to produce maximum yields. Others simply start out with the plan to harvest corn for grain, but, instead, cut it for silage if rainfall is lacking."

In either case, the irrigation requirement is less than that for grain corn that must be irrigated later in the season to fill ears. "We've grown silage a couple years here at the research farm, but it's probably something we should investigate a little more," he says.

Ultimately, Marek says everything has its advantages and disadvantages. "Hopefully, what we learn here will help producers make informed decisions as our research results filter down through university partners, consultants, and the Natural Resources Conservation Service districts."