:max_bytes(150000):strip_icc()/CropXReinkeCorn-85a0cfa66c5344c99705818a6997784c.png)

Crop X

Nick Emanuel farms 2,000 acres of corn and soybeans in North Bend, Nebraska. He has seen the benefits of utilizing soil moisture probes on his farm.

“We’re seeing savings across the board starting with water savings, but also our electricity usage that runs the pivots,” he says. The probes save him an average three to four rotations per year, including about $1,100 in electricity for each rotation. “The more pivots you have,” he says, “the more that adds up.”

Soil sensors are one way farmers can dial in their irrigation scheduling and fine-tune variable rate irrigation (VRI), explains John Gates, chief revenue officer with CropX. The company uses artificial intelligence (AI) and other technology to help farmers manage operations.

Compared to previous irrigation scheduling methods based on educated guesses of moisture availability, Emanuel says soil sensors offer an in-depth analysis of actual soil moisture, crop water use, and overall crop health.

Gates recommends one sensor per quarter-section pivot to aid in scheduling. For VRI he recommends bumping that up to three.

“You’re using the pivot to put on more water in some areas, less in other areas, in order to do some problem solving,” Gates says. “Maybe it’s around soil variability, topography, or compaction.”

Emanuel says using CropX soil sensors, he’s also noticed increased fertilizer efficiency.

“With our old irrigation practices, there was a tendency to overwater, and each time you’re overwatering, it increases the risk of leaching nutrients through the profile,” he explains. “It also creates an anaerobic environment, which prevents the crop from utilizing nutrients efficiently. Through in-season tissue and soil sampling [with the soil moisture probes], we’ve seen a direct correlation with better nutrient uptake getting into the plant.”

Monitoring evapotranspiration

Tracking evapotranspiration (ET) rates is another traditional method for irrigation scheduling. Calculations can be cumbersome, and ET is usually estimated. Reinke Direct ET by CropX provides actual evapotranspiration (ETa) measurements via a sensor mounted on a Reinke center-pivot irrigation system.

Direct ET offers measured, field-specific values without needing additional calculations.

Placed above the plant canopy on the center point of the irrigation system, the device uses surface renewal technology to measure the amount of water vapor the wind carries away from the crop, Gates explains.

:max_bytes(150000):strip_icc()/ETSensorSoftwareView-6ec4547dcccf429091c6328cc5ff89d9.jpg)

CropX

Measuring the amount of crop-used water gives farmers daily insights into their fields’ water needs. “This accuracy allows farmers to apply water only as needed, directly addressing the plant’s requirements,” Gates says.

“It’s really a totally different way of measuring crop water use,” agrees Emanuel, who beta-tested the Direct ET sensor on his farm last summer. He notes that soil moisture probes can often mean extra work, installing them at the beginning of the year, then removing them before harvest. The ET sensor, however, “provides a little more flexibility, where it’s really just a one-time install in the pivot, and it’s going to be there from year to year.”

Emanuel says he felt confident with the data it provided for the specific crop and individual fields. “I think there’s potential moving forward to complement working together with the soil moisture probe to give us detailed soil moisture readings below the ground, and then crop water usage from the Direct ET aboveground,” he says.

Digital tools

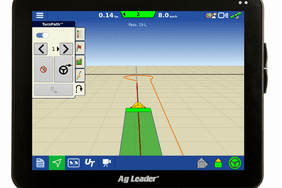

Sensors are not the only way to dial in irrigation accuracy. Lindsay Corporation and Valley Irrigation offer digital platforms to inform irrigation management decisions.

Earlier this year, Nebraska-based Lindsay updated their digital FieldNET platform, called FieldNET Next Gen, which allows farmers to manage pivots, laterals, pumps, alerts, and data, all from one place.

Justin Gibson, Lindsay’s senior manager of digital agronomy, describes FieldNET as a “sensorless, purely digital tool” that ingests data such as weather, soil, satellite imagery, and irrigation application. The company tracks how much water has been applied to the field. That information is entered into a crop model, which employs layers of localized weather data, soil moisture, and crop water to simulate soil moisture and crop water use. “We can give a recommendation to that grower every day for every one of their fields and their FieldNET connected operation,” Gibson says.

For farms with VRI-capable pivots, FieldNET also can generate variable-rate irrigation maps, enabling sector-by-sector application. “If they have a VRI-capable pivot with nozzle control,” Gibson notes, “we can even make them a nozzle control prescription based on FieldNET Advisor.”

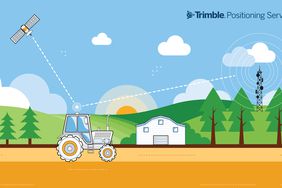

Valley, also based in Nebraska, offers a single platform to manage a range of technologies including Monitoring and Control, Forecast and Plan tools (Irrigation Scheduling), Optimize and Apply tools (VRI), and Irrigation Insights.

Irrigation Scheduling allows farmers to view data on soil moisture, crop type, stage of development, and automatically updated weather information, and generates irrigation forecasts based on this data. “Scheduling analyzes the water balance in your field at any given time and recommends the appropriate amount of water to add, based on the crop and the field’s water capacity,” says Lior Goren Ruck, vice president of Prospera software products by Valley.

:max_bytes(150000):strip_icc()/ValleyScheduling-b36501f5ae934408b4ea7b0f5855e51b.jpg)

Valley Irrigation

Pivot Monitoring and Control allows farmers to control their pivots remotely. “With Valley 365, growers can integrate all these products,” she explains.

“For instance, you can view your irrigation forecast in the scheduling product, determine the necessary water amount, then switch to the monitoring and control section of the app to send a command to your pivot.”

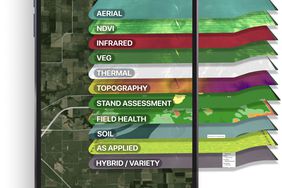

Irrigation Insights leverages imagery and artificial intelligence algorithms to virtually scout fields. Insights sends alerts for any watering irregularities, pivot-related issues, or crop health concerns, allowing growers to adjust pivots, maintain crop uniformity, and reduce overall input costs.

:max_bytes(150000):strip_icc()/ValleyIrrigationInsights-dd968a7198254e7aa8c9d5a0ed1f5f4f.jpg)

Valley Irrigation

Goren Ruck says what’s really powerful about these products is “their ability to work together, addressing all decision points and needs that growers have in planning, operating, and managing their irrigation side of the farm.”

Digital tools, Gibson says, can reduce irrigation applications but retain the same yields. “They also have peace of mind and a reduction in the amount of time they spend making plans for irrigation across the operation,” he adds. “We’re making that decision easier by crunching all the numbers for them automatically.”

:max_bytes(150000):strip_icc()/AdrienneHeld4x5crop-a7e3515671bc41c28273a85982f2c67e.jpg)