:max_bytes(150000):strip_icc()/img_54174f1096c3f_45126-6705ccd1a39a4f87bbfce05ceed8b6ad.jpg)

Gary Schreiner remembers, at age 12, fighting with a plastic grain hopper that twisted, flopped over, and left grain spilling onto the ground. Today, 38 years later, he's fixed the problem, patented the invention, and has started manufacturing it at his company in Swift Current, Saskatchewan. He calls it the Auger Hog.

Over the past four decades, grain augers, conveyors, trucks, and bins have grown. Plastic hoppers have gotten bigger and harder to move. Some high-capacity hoppers are too tall to fit under grain trailers and older low-bottom hopper bins.

Injury causes action

Three years ago, Schreiner put a rope on a big plastic hopper to pull it from bin to bin with an ATV. It was holding about 100 pounds of grain that had refused to clean out.

"I was trying to push it under an older hopper bottom bin, and it was a tight fit," he recalls. "I slipped and fell, hurting my back really bad. Then I tried pushing it with the grain auger and broke yet another plastic hopper. That was when I decided it was time to make a proper grain hopper."

While he still farms in the Saskatoon area, Schreiner is an inventor with several patents and is president of Gatco Manufacturing. Gatco manufactures aeration systems for grain bins.

"I spent the next three years building the perfect adjustable grain hopper," Schreiner says. "A lot of technology is built into it to make it, in my opinion, the only grain hopper that works."

The bottom portion is made with 14-gauge steel. A wide skid plate on the front of the hopper enables it to slide easily on the ground. The skid plate has a door that slides sideways for cleanout (without hinges). It cleans out into a 5-gallon pail with no mess.

The basic design prevents grain loss due to spitting, blowing, or overflow. It increases average auger capacity by 20% to 30%. It can be used with an auger or a grain conveyor.

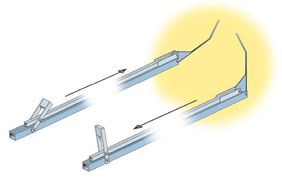

The Auger Hog has a high U-shape wall pattern, taller than the auger flighting and long enough to catch grain that can spill back where the flighting runs into the auger tube. The high U-shape lets gravity drain grain into the auger.

At the end of the U-shape pattern, another wall stops grain from going past the auger's infeed tube.

Adjustable top

The adjustable top of the Auger Hog features new technology.

A four-sided steel hoop, 36 by 40 inches, is able to enclose a whole grain trailer door.

Industrial-grade canvas joins the rectangular hoop and the U-shape walls, enabling height to be adjusted. At its lowest, the hopper can operate at 12 inches above the ground. With the aid of a cranking handle, the hoop can be raised to 28 inches and locked into position at any point.

Schreiner says this design keeps flowing grain piled above the auger or conveyor infeed and boosts capacity.

To attach an auger, the Auger Hog just slides over the infeed end of the auger and pins into position. In five seconds, it can be on or off.

Auger Hog models are available for 8-, 10-, 12-, and 13-inch augers. Price starts at around $1,100.

Learn more

Gary Schreiner

306/291-9960

gary@gatcomfg.com