:max_bytes(150000):strip_icc()/arizona_371632125B15D5B15D-2-2000-b75b2ceecae34387977000ae90016a48.jpg)

Sustainability. It's been a staple of farm life for as long as crops have been grown. The term, which is often described as "humanity's target goal of human-ecosystem equilibrium," has become a buzzword in many businesses today. While some corporate sustainability programs focus on public relations, others show genuine concern for natural resources with the emphasis often on water.

Levi Strauss, for example, conducted a comprehensive life cycle assessment and found that one pair of its 501 jeans uses nearly 1,000 gallons of water in its full life cycle – from growing cotton, through manufacturing, consumer care, and disposal. The company began its water sustainability program by focusing internally, and through a series of innovative finishing techniques, it reduced water use in the process by nearly 96%. It also discovered nearly 70% of that water went toward cotton production.

"Knowing that 95% of Levi Strauss products are cotton-based, this meant reevaluating the sustainability of our cotton supply and finding new solutions to address this raw material's impact – from irrigation and runoff to pesticides and farmer education," states the company's website.

better cotton initiative

The solution was the Better Cotton Initiative (BCI). This global project, cofounded in 2005 by Levi Strauss and others in the textile industry, focuses on decreasing the environmental impact of cotton, improving labor standards, and increasing the economic livelihood for farmers. It also requires that farmers use water efficiently and care for its availability. BCI reports that in the many countries it operates in, farmers use up to 18% less water than non-BCI farmers in comparable locations.

"In 2015, we sourced 12% of our total cotton through BCI – up from 7% in 2014," the website notes. "By 2020, our goal is to use 100% sustainable cotton through sources such as BCI and recycled cotton, significantly reducing our total water footprint."

"We count about 70 retail and brand members around the world, including GAP and Nike, who are members of the initiative," says Scott Exo, USA country manager for BCI. "We're not trying to tell farmers what they have to do or by what percentage they have to reduce water consumption. However, our principles and criteria do state they have to adopt a water stewardship plan to help protect and conserve local water resources."

That includes mapping water resources, managing soil moisture, and applying efficient irrigation practices to optimize water productivity and sustainability.

Todd Straley, manager of the Quarterway Cotton Gin in Plainview, Texas, and an ambassador for BCI, says members of the Quarterway Cotton Growers don't have any trouble meeting the initiative's mandates.

"We're in a rapidly declining water table area," Straley explains. "We're limited by the High Plains Water District to 18 inches of water annually; but I don't have any customers who could reach that 18 inches if they wanted to. Some only have enough well capacity to pump 10 to 12 inches annually. We have to use water as efficiently as possible."

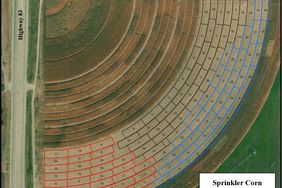

Consequently, he has helped many of his customers adopt low energy precision application (LEPA) systems, including bubblers that operate at low pressures ranging from 6 to 20 psi. These systems also deliver at least 20% more water to the soil than conventional spray nozzles.

"Some growers have also installed drip irrigation systems," Straley adds. "Drip can cost around $1,200 per acre to install, but through government cost-sharing programs, they can get that down to about $600."

Drag hoses work well, too, he notes, referring to the emitter hoses that replace the nozzles on a center pivot. Dragged behind the pivot, they deliver irrigation water directly to the soil surface.

"Unfortunately, Environmental Quality Incentives Program (EQIP) will not yet cost-share on drag hoses like they will drip irrigation and LEPA," says Straley. "Whether it's drag hoses or bubblers, the key is to deliver water in the furrow and get it as deep as you can as fast as you can. The closer it is to the soil surface, the more likely it is for some of it to evaporate."

sustainable farming initiative

PepsiCo, which sources everything from potatoes to oranges and corn syrup, has also launched its own sustainable farming initiative. Its goals are to sustainably source direct agricultural raw materials by 2020 and to source nondirect major agricultural raw material ingredients by 2025. That includes improving the water-use efficiency of its direct ag supply chain by 15% in high water-risk sourcing areas. One way it's done that is by partnering with groups like The Nature Conservancy.

A recipient of this partnership is Hauser and Hauser Farms, the largest multigenerational operation in Arizona's Verde and Salt River watershed. Both rivers are part of the Colorado River system, which is the primary source of water across the Southwest including Pepsi bottling plants in the Phoenix area.

"The Nature Conservancy helped us put in automated head gates with motors at several locations on the irrigation ditch and on a pond," says Zach Hauser, part of the farm's third generation. "This allows us to control the opening on each gate with a smart phone. It also put gauges throughout the ditch system so we know exactly how many cubic feet are moving through the ditch. Any water not used is returned back to the river."

The nonprofit also helped convert several fields from flood to drip irrigation and provided the resources to install a microsprinkler at the base of each tree in the farm's 35-acre pecan orchard.

"We don't really have a way to quantify water savings, but I would estimate we're using about half of what we once were. As a result, we're converting more acres to drip or microsprinklers each year," Hauser says.

In addition, The Nature Conservancy assisted an area group in opening Arizona's first malt house, which has helped producers not only maximize revenue from barley but also reduce water consumption.

"Due to the new market, we switched some corn and alfalfa fields to barley," Hauser says. "We can sell the malt house our barley at a good price. It also means more water goes back to the river. Unlike corn and alfalfa, which require water all summer, we're done irrigating barley by the end of May."

initiating change

Ward Neeson, chief information officer for Wysocki Family of Companies in Bancroft, Wisconsin, says his employer has not yet been asked to reduce water use, even though it supplies potatoes to a major snack food company. However, its agronomic staff has been involved in a number of research committees where this topic is actively discussed.

"The problem with stipulating a percentage reduction is there are so many variables from year to year," says Neeson. "Still, I believe there will come a day when large retailers and end users will say they want you to use X amount less water or to demonstrate you are using the minimal amount needed to grow a crop."

Yet, Wysocki Farms has already taken the initiative, if for no other reason than to save money and reduce input costs. Scouting teams check fields two to three times a week, probing the soil to measure moisture and monitoring canopy cover.

"We're also following research focused on learning at what point in the crop's growth you can stress the plant without affecting yield," Neeson says. "Finally, we're a heavy user of technology," noting that its latest forecasting tool combines data collection with analytical software to provide irrigation recommendations at each stage of plants' growth.

"In fact, we were part of the pilot program for FieldNET Advisor and are making every effort to have all 300 of our potato fields on the program," he says.