:max_bytes(150000):strip_icc()/img_560da701e8cb8_50539-8c92426f88f349f084cd7ac5a8d4c3b4.jpg)

If you had told Tim Schmeeckle three years ago that he could irrigate 20 acres of corn with a 3.5-hp. submersible pump, he would have thought you were clueless about farming.

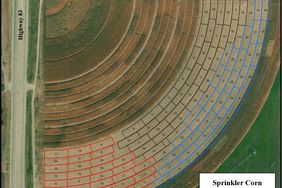

Yet, for the past two years, the Gothenburg, Nebraskan not only has irrigated that 20 acres on a pauper's budget, but also has seen similar success irrigating 30 acres on the other end of the field with a 7.5-hp. pump. What's more, he couldn't see any difference at harvesttime between that 50 acres and the corn under center pivot irrigation right next to it.

Since Schmeeckle had already been experimenting with variable-rate irrigation on the 2,000 acres he farms, he was more than willing to conduct a test trial for the latest subsurface irrigation system. Codeveloped by Valmont Irrigation and DuPont, Root Demand Irrigation (RDI) consists of a series of porous subsurface tubes positioned below the root zone.

Subsurface tubes dole out water as needed

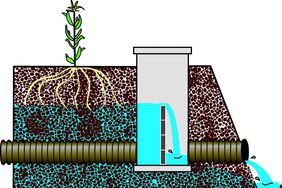

If you think of RDI as drip irrigation, though, the fact that both are buried in the root zone is where the similarity ends. "Unlike other types of subsurface irrigation products, RDI is porous along the entire length of the tube," says Jake LaRue of Valmont Industries. "The biggest advantage is that, unlike other forms of irrigation, RDI doesn't use the soil as a repository to store water between irrigation cycles."

Instead, RDI uses the subsurface tubes as the reservoir and relies on the plant roots to release water for meeting the demands of the plant. While this sounds a bit like science fiction, LaRue explains that the tubes hold the water at a pressure just below a point that would break the surface tension of the liquid. Surface tension is, instead, broken by root exudates to meet the needs of the plant.

Root exudation

Root exudation can be broadly divided into two active processes, LaRue continues.

"The first is root excretion of waste materials, while the second is secretion of compounds with known functions such as lubricants and defense. It is the second type of exudates that breaks the surface tension of the water, releasing it," he says.

"The idea is both fascinating and far-fetched," he says, noting that his trial field was in the second year of corn-on-corn. "It seems to work. That field where we tried it is particularly challenging since it's an odd-shape field. It has a double swing-arm pivot with what I would call a tag arm on a corner pivot. Yet, it still left areas on each end that could only be irrigated with furrows. To make that work, I had to run the furrows in different directions because of the field grade."

Employing the RDI system, Schmeeckle was able to water both ends of the field at a much lower cost than furrow irrigation.

"Even better, I can have all the rows running the same direction," he says.

Schmeeckle admits he and Valmont did see a few challenges related to field contour. That was also part of the reason Valmont selected his farm for one of the initial trials. Of course, Valmont didn't limit its RDI trials to Nebraska.

Floridian farmer's experience with RDI

Some 1,500 miles away, James Williams, who owns Tri-Country Irrigation in Live Oak, Florida, and farms nearby, evaluated the RDI system on a 5-acre plot. While Williams normally plants peanuts under his pivots with corn as a rotation crop, the test field was planted entirely to corn with the RDI installed on one of the corners on a 160-acre circle.

"The biggest issue we have is the sandy soil," Williams explains. "Last year was our first year with the system, so we had a few issues. I think we'll have a better handle on it this year. Even then, the savings on water and utilities quickly make up for any shortcomings. Considering that this was our first year with something so new and unique, I was pleased."

Williams says part of the reason he picked the one field in particular for a trial was that it already had a small 4-inch-diameter well next to it. So all he had to do to supply the RDI system was install a 3-hp. submersible pump.

"The only problem I can see with the whole system is that I can't water a field to help with germination," he says. "Our fields are so sandy that it's hard to hold any water in the soil for very long."

Schmeeckle noted the same issue, adding that the RDI tubes are typically buried about 14 inches deep. On the other hand, he believes that a lot of farmers start irrigating too early anyway.

"I remember when we didn't start furrow-irrigating a field until we had ridged it during cultivation," he says. "Now that everyone has pivots, it's almost too easy to overwater. Too much water too soon doesn't force the roots to go down deep enough to pick up reserve moisture. Then you often have to water it even more, since it has a shallow root system, and you run the risk of having it lodge because it doesn't have enough of a root system to anchor it."

Roots reach water

Consequently, Schmeeckle doesn't have any problem with forcing the plants to reach down to where they can tap into the RDI tubes on their own.

"In the places where I've checked, the soil is wet from 4 to 6 inches from the tube," he says, noting that tubes are buried every 30 inches. "In the meantime, the pressure in the tubes is only around 2 pounds per square inch, so the system only provides what the plant can use.

"The bigger issue, though, is that it requires a lot less power to run the whole system," he continues. "In comparison with the 7.5-hp. motor on the 30 acres with RDI, I have a 38-acre pivot directly across the road that uses a 60-hp. motor. That's a big difference."

Won't replace pivots

Schmeeckle doesn't expect RDI to replace pivots. It has a future in much of Nebraska, though, particularly on pivot corners that are relatively flat.

"Right now, those areas of the field are either in wheat or dryland corn that I plant at about half the population of the rest of the field," he says. "I don't know yet what the cost per acre will be for the RDI system, but it will certainly be something to look at down the road."

Yields are similar

Yields from small trials have compared well with those from pivots and other forms of subsurface irrigation, LaRue says. "Plus, we've seen the potential for RDI to complement center pivot and linear irrigation," he says.

Now, he says, it's time for research that involves "larger field trials and more work to better describe the characteristics, such as uniformity along longer noncoated, nonwoven, porous tubes."