:max_bytes(150000):strip_icc()/agri-inject-2000-7a2d6b9e073a402fa6debcc49da52d12.jpg)

Imagine being able to apply variable-rate liquid nitrogen through a center pivot irrigation system while, at the same time, varying the amount of water being applied. According to Caleb Schultz, precision ag manager for J.R. Simplot Company in Wray, Colorado, such technology is no longer a dream but a reality.

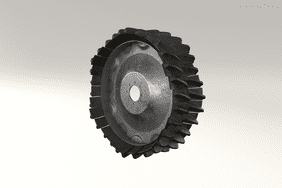

Schultz was one of the first to use a new reflex variable-rate fertigation (VRF) system introduced by Agri-Inject, a manufacturer of chemigation systems and fertilizer injection pumps based in Yuma, Colorado.

Matching flow to changing conditions

As Neal Saxton, director of global sales for Agri-Inject, explains, the reflex intelligent injection-control system was actually introduced nearly two years ago to provide responsive control of fertilizer or chemical flow into the system to match changing irrigation conditions. Whether the variable flow rates are the result of a corner span extending, change in pivot speed, or changing flow rate from the pump, reflex senses changing water flow rates and automatically adjusts the rate of the injection pump to ensure consistent fertilizer dosing.

"Since then, we've used that flow-based injection technology to develop intelligent injection control for VRF," he relates. "Now, you can apply fertilizer through the pivot to either match flow rate or to match a fertilizer prescription, just as you vary water applications to a prescription. In fact, reflex even allows you to variable-rate water and fertilizer applications independently."

Schultz says his experience with VRF began in 2014 when he programmed a system on a customer's field for a flat-rate fertilizer application, even though the pivot was programmed for variable-rate irrigation. The reflex system compensated for an increase or decrease in the amount of water applied to different sections of the circle to maintain an even fertilizer application over the entire crop.

"We call it flat-rate injection, but actually the injection rate was constantly changing as the pivot speed increased or decreased in relation to the water prescription," he explains, noting a client in Nebraska did the same thing this past summer.

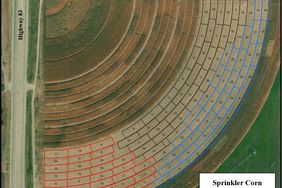

"For the second phase, which was implemented this past season, we kept the irrigation rate the same over the whole field and varied the fertilizer rate through 20 to 30 pie-shape segments of the field," Schultz says. "Next year, we hope to tie both together and variable-rate irrigation and fertilizer. Those are really the three methodologies for using the system."

The reflex system works with any Agri-Inject metering pump and irrigation systems that have an existing variable-rate irrigation (VRI) controller. This includes the VRI controller on Reinke systems, as well as systems with an AgSense controller.

The list price of the reflex system without a flow sensor ranges from around $4,000 to $10,000, depending on existing equipment, such as the injection pump and plumbing. Depending on the dealer, the installed price may vary.

"The system has to already be set up for variable-rate irrigation, though, for this to work," Schultz insists, noting that VRF prescriptions are based on the same 6° pie shapes that are available for variable-rate irrigation prescriptions.

"Of course, the one advantage of VRF is you can still vary the nitrogen application rate at the crop stage where it is too late for variable-rate preplant or sidedress applications," he says.

Schultz points out that the pivot circle is also divided into five zones that are totally random across the field, which means they often span across the pie segments. Each zone is, in turn, rated from 1 to 5 on fertility, with 5 being the best.

"Those are sampled every year for nutrients," he says. "We determine what nutrients are left in the soil at the end of the season. Then, we adjust the yield goal, minus the carryover, and that basically tells us what our nutrient requirements are for the year."

Prescription formulation

To help determine fertility needs, Schultz says he also relies on several years of yield data, along with ongoing leaf samples and infrared images from a satellite owned by the agribusiness company. This was particularly important this past spring and early summer when heavy rains had a tendency to leach nitrogen from sandy soils rather quickly, making several small fertigation applications even more important.

"The way it works is, we may determine that in zone 1 we want 10 gallons per acre of nitrogen, zone 2 is 11 gallons per acre, and zone 4 is 13," he says. "Our program then looks at each pie segment and determines the average zone number in each. Let's say one pie segment consists of 50% zone 1 and 50% zone 4. The prescription is going to average it out and apply about 11½ gallons per acre to that section. That can change during the season based on tissue samples."

Schultz recalls that the rates on the test field ranged from around 10 gallons of nitrogen per acre to 15 gallons per acre, or about a 50% difference from the best areas to the weakest areas.

"When you talk about variable-rate anything, people always want to talk about input savings. However, the primary goal is always input efficiency," says Schultz.

"Just as it is with variable-rate application of dry fertilizer, the goal is to redistribute fertilizer, putting it where it will do the most good and cutting back where the potential isn't there. Ultimately, you're focusing on reaching optimal yield per acre based only on each segment's real potential. Naturally, we always calculate the yield average across the field after harvest and compare it with historical averages to see how much difference it actually made overall," he says.

"We've done variable-rate injection in the golf course industry for years," Saxton says. "There were limitations with that technology when it came to agriculture. That is, until we came out with the reflex system."

Versatility plus

Schultz says the versatility isn't limited to VRF within a single crop. "A client in western Kansas has a large section pivot that covers multiple crops with different fertility needs," he says. "Basically, he wanted to make things a lot simpler and is using VRF to apply different rates of fertilizer to each crop, even as the pivot makes a full circle."

Versatility is the best part about the system, says Saxton.

"There may be times you want to vary fertilizer in a direct relationship with the water application, injecting the product in proportion to the flow," he explains.

"Other times, you may choose to put a little more fertilizer on one area, even as the water rate is reduced. Or, there may be instances where you want to run water at 90%, while cutting fertilizer to 70%," he says.

"With the reflex system, you can do any of those things – and it takes as little as five minutes to set up the reflex panel and program the rate," he says.