:max_bytes(150000):strip_icc()/102707983-2-2000-8cb32049a2954e389230b367c307019c.jpg)

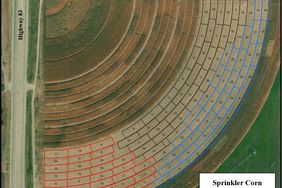

With 57 center pivot units scattered over five counties, Darrell Wood and his sons, David and Clayton, would have a hard time getting anything done other than checking pivots if it weren't for remote monitoring and control.

Even today, only about half the pivots on the Woods' central Kansas operation, based south of Belpre, are equipped with Wagnet (wireless agriculture network) units. As a cloud-based dashboard that works with AgSense, Wagnet allows family members to manage the pivot operation via any smartphone or tablet that has access to the Internet.

15- to 20-mile remote control reach

The farthest pivots are 15 to 20 miles away. "So, we started adding remote pivot control on those that are the most distant and started working our way closer to the farm. That alone saved a lot of time and fuel," says David.

One exception is a pivot located only 2½ miles away that is supplied by a well that only produces about 600 gallons per hour. In that case, remote pivot control was added as a peace-of-mind feature.

"Under normal circumstances, we might check it during the day and not find out until several hours later that it was running low on water," Clayton says. "With remote monitoring, we know right away if there is a drop in pressure."

Darrell says remote pivot management also provides the benefit of water conservation, even though the family is not yet under water restrictions. "If we have the pivots running and the afternoon turns extremely hot and windy, rather than lose part of our water, we can just turn all the pivots off," he says. "Then, at about 7 p.m., we can start them back up when conditions are a little better."

Peak electrical shutdowns

Ironically, the Woods aren't the only ones who can turn off the pivots. Since all their pumps are electrically driven, the Woods have an agreement with Midwest Electric (one of their utility providers) that allows the company to shut off the wells during peak energy demands.

In exchange, the company provides the Woods with lower electric rates, along with remote monitoring of the wells. They also get notification via their cell phones when the wells will be shut down. Naturally, when the well pump is shut down, so is the electric pivot.

"The electric company tries very hard not to abuse the privilege," Darrell says. "There have been years, in fact, that it only happened a couple times per summer. In the meantime, our electric bill is about a fourth less." If the Woods needed yet another reason to install remote pivot control on their pivots, David insists the ability to check on pivots via their cell phones also allows them to focus more attention on their crops.

"It definitely gives us more time to scout fields and to manage fertility," David says. "Plus, it allows us to stop the pivot in a certain position if we need access to the field or if we need it moved off to one side."

To that end, the Woods apply at least 70 units per acre of nitrogen through the pivot each year at a time when the crops need it the most. They don't, however, depend on remote monitoring to manage fertigation.

"We still monitor fertilizer injection ourselves," Darrell says. "We don't want to risk having a hose break or something else going wrong and not knowing about it. Plus, we don't generally start a pivot remotely. We sure can't beat remote management, though, for monitoring a pivot or shutting it down when we're just applying water.

"I can see a time in the not-too-distant future when we will have remote monitoring on everything," he concludes. "There are just too many advantages to having it."