Bill Kranz

University of Nebraska

Wear and tear on irrigation pumps and motors can contribute

to a gradual decline in water application efficiency that may not always be

easily identifiable. Regularly recording the static and pumping water levels,

output pressure, flow rate and energy use provides an excellent reference for

evaluating pump performance. Without records, you may not be aware of how

system performance has changed over time.

Each irrigation system should be equipped with a recently

calibrated water meter, pressure gauge, and a means of monitoring the water

level in the well (air line or a hole for an electric resistance probe). Gauges

to monitor such variables as motor water temperature, oil pressure, revolutions

per minute, and hours of operation should be maintained to provide a means for

monitoring the system as well as shutting it down if it is not working at the

appropriate level.

Other motor records should include hours of operation, oil

and fuel use rates and engine operating temperature. Engine overhauls and part

replacements are easier to plan for if hours of operation are recorded.

In the spring, check control boxes, pipelines, the engine

compartments, and exterior oil cooling coils for rodents. Also check all wire

coverings which rodents may have damaged, creating the potential for electrical

shorts. Corrosion also can contribute to wiring problems. A pre-startup check

of all electrical connections will reduce the chance of electrical failure or

personal injury.

Before the first irrigation next spring, check your owners

manual and perform routine maintenance, including:

- Change the engine oil and filter,

- Check drive belts (if any),

- Grease all drive shafts on pump, and motor,

- Replace fuel filters,

- Check the operation of the chemical injection pumps,

- Check and clean the battery power cables,

- Drain, flush and refill the cooling system,for 30-60 minutes.

- Drain and replace the lubricating oil in pump gear drive,

- Refill the reservoir for lubrication of the pump drive shaft,

- Check the gear drive to be sure it is free moving and clean the non-reverse

pins with a wire brush, and lubricate each pin, - Start the motor and allow it to run at 1000 rpm

Some pump installations may not require all of these

maintenance checks or they may require different or additional repairs. Check

your owner’s manual for what best suits your system.

The water distribution system, especially the drive tower

tires, gear boxes and alignment panels, also need routine maintenance. Oil

lubrication of the gear boxes is essential; bearings and seals should be

checked regularly. Lubricating oil containing water, or steel filings can

drastically increase the wear and tear. Drain any water out of the bottom of

the gear box prior to each irrigation season. Refill gear box oil annually and

replaced it after the first irrigation season and every 3000-4000 hours of

operation thereafter.

With hydraulically driven systems, check for oil leaks. Oil

distribution hoses degrade over time and should be closely inspected for

severely worn or degraded areas. Ruptured hoses are costly in terms of oil

spillage and present a safety hazard to operators. Rather than chance a

breakdown, replace hoses that appear to be a hazard.

Most self-propelled systems have numerous moving parts that

require lubrication. Begin each season with every grease receptacle and oil

reservoir filled to the recommended level. All electric components should be

sealed to prevent bugs, dust or rodents from damaging components, which could

lead to system failure or personal injury.

Irrigation systems are equipped with safety switches

designed to shut the system down under specific conditions. These switches

normally include a low pressure shutoff, system alignment and over-watering

safety, end gun control and automatic shutoff at the end of a revolution. Your

system may include other switches. Test your system by running it and creating

situations which should prompt the safety switches to shut the system down. For

example, to test alignment control, start and stop the system several times

while moving both forward and in reverse to determine if the system realigns

itself. If not, determine why not.

Finally, many systems utilize on/off control of the end gun.

This feature is used to accommodate roadways, farmsteads or other areas where

irrigation is unwanted. The switch activates a solenoid valve to cutoff flow to

the end gun. Pressurize the system and determine if the switch is functioning

properly and check for a leaky solenoid valve.

Sprinkler nozzle wear depends on the quality of the water

and the system operating pressure. Sprinklers will need to be replaced more

often on systems operating at high pressure than those operating at low

pressure. A walk by inspection of the system can identify sprinklers that are

plugged, badly worn or not operating properly. Generally, plan to replace

sprinklers after about eight to 10 years of use. Systems with extremely low

water will experience problems sooner.

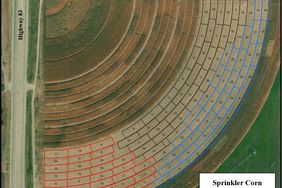

Walk-by inspections can indicate sprinkler maintenance

needs, such as pressure regulator failure or non-operational sprinklers. Often

these problems can go unnoticed during the irrigation season. Some problems can

be seen from a distance while others will require more scrutiny to identify.

For water to be applied uniformly, all nozzles or sprinklers must be

functioning properly.