:max_bytes(150000):strip_icc()/Nelson20Acelerator20center20pivot20nozzles20on20corn5B15D-2-4e9a49e69d1d4e048012e2e32ad8d38b.jpg)

Fields laid bare from harvest offer a great opportunity to inspect center pivots for repairs or to evaluate their performance before putting them to bed for the winter. Steve Melvin of the University of Nebraska says many suppliers feature excellent off-season service specials at this time.

A key performance check that is often overlooked is sizing up a pivot's operating pressure. Also, measuring a system's flow will help with diagnostics.

In order to check pressure, you'll need a working pressure gauge and an understanding of operating pressure design for your system, Melvin explains. The best place to find designed operating pressure and flow is to reference the sprinkler chart, which came with the sprinkler package when it was purchased new with the pivot or as a replacement package. This information is often placed in the center pivot's panel.

The sprinkler chart is different for almost every pivot because every package is custom designed for that system's flow rate and length. The sprinkler chart contains a lot of information, including:

* Designed operating pressure and flow rate

* Details about positions of all the sprinklers

* Length of each span and overall length of the pivot

If you cannot find the chart, request one from the dealer who sold you the sprinklers.

pinpoint pressure

Measure pressure both at the pivot point and near the end of the pivot, Melvin says. "Check the pressure at the end of the pivot when the last tower is in the highest point in the field. For the regulators to work correctly the pressure in the pivot mainline needs to be at least 5 psi over the rated pressure of the regulator," he says.

Assuming the pressure was correct when the sprinkler package was new, if the pivot's pressure is now too high the cause is likely plugged nozzles or restrictions in the pipeline.

If the pressure is too low, that can indicate too much water is exiting the pivot (likely due to leaks) or that there is a problem with the pump output. A flow meter is a helpful tool in this situation because it will tell you if you have more or less water flowing through the system than the design calls for.

"Sometimes producers assume the flow meter is bad if the flow is different than what the system is designed to provide," Melvin says. "If this is a concern, the flow meter can be removed and tested by the manufacturer."

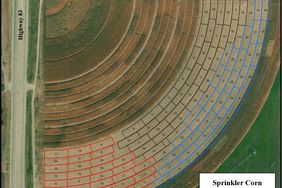

Low pressure with high flow rates indicates that more water is leaving the pivot system than was designed to, Melvin says. The excess flow can be coming from leaks, bad pressure regulators, or worn or missing sprinklers. Often, these problems can be seen by looking at the water pattern coming out of the pivot with the sun reflecting on it in the morning or in the evening. In a properly functioning system, the water distribution should appear even with a gradual increase in water volume from the center point to the outer end.

Worn-out pressure regulators and sprinklers can be hard to see, however, so consider replacing them every eight to 10 years.

When looking at the sprinkler pattern, also note broken or missing sprinklers and damaged rubber boots where the spans connect. If a sprinkler needs to be replaced, take it to the dealer or look it up in the sprinkler chart so you get the correct regulator and sprinkler with correct nozzle size for that portion of the pivot.

Another good way to evaluate the sprinkler package is to look for nonuniform circular patterns in the crop. Often they become visible aerial images or, if bad enough, from the combine cab at harvest. Do not rely on the combine yield monitor to pick up sprinkler problems, however, because those areas are usually fairly narrow and the width of the combine head will often collect grain from both poorly and well-watered areas, Melvin warns.