:max_bytes(150000):strip_icc()/img_52d566e56f55d_41122-f2d9f12e513142ce9e72a87f575b0383.jpg)

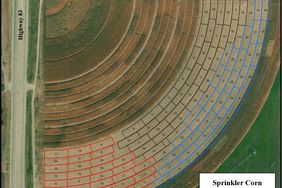

Frustrated with the jarring effects of center pivot tracks, Dan Gillespie employed his considerable inventing skills to engineer a tractor-mounted attachment that makes quick and thorough work of the chore.

The Battle Creek, Nebraskan has been running his TracPacker for the past three years, proofing and perfecting its operation. Gillespie has the design working to the point that it closes and then packs even the deepest ruts in one pass.

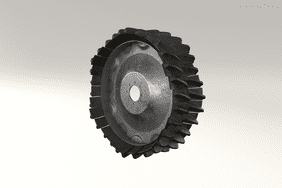

"I wanted something that would give me the right amount of soil – not too much, not too little," he explains. Key to his TracPacker's success is a depth gauge wheel that runs in the pivot track. The wheel automatically adjusts the operating depth of trailing filler disks that flow dirt into the track.

"I wanted to look at what I was doing. So I mounted the device to the front of the tractor," Gillespie says.

The tractor's right rear wheel provides the ideal solution to pack the soil mounded on the rut. "Packed soil is less apt to erode, and packed tracks are less inclined to form the following year," Gillespie says. Plus, the TracPacker disturbs only an 18- to 50-inch width of the field, depending on the depth of the track. Utilizing a 12-foot disk (to fill tracks), on the other hand, tills up about 11 acres in fields with a 10-tower pivot.

Since Gillespie is also a no-till farmer, he wanted to keep the amount of disturbed soil to a minimum.

Floats to fill a track in two hours

Once the TracPacker is lowered into the track and with the tractor's hydraulic system positioned in the float setting, the implement is free to move up and down as the track depth varies.

"With a tractor speed of 4 to 5 mph, I can fill and pack a pivot's tracks in less than two hours," Gillespie says. "Center pivot electric motors and gearboxes operate with less stress if the tracks are properly filled and packed, thus, reducing downtime and maintenance."

Not all of the four filler disks that operate on each side of the track vary in diameter. From their position inside to outside, they are 18, 20, 18, and 16 inches in diameter, respectively. The outer disk blade on the side unit is also equipped with a depth-control band to keep it from tilling too deep.

:max_bytes(150000):strip_icc()/pivottracks2-c0d0c6eb7ec64b72b34d1f38ed8da97c.jpg)

Working on the design since 1994

Minimizing tilling to fill tracks was a crucial design element of the TracPacker to Gillespie since he does no-till on his farm. The concept for the implement began in 1994 with a design made from an old IHC disk.

By 2001, he had a prototype of the present implement, which he showed at an irrigation workshop from his location's natural resources district. Stuart Hoff, research farm manager at the University of Nebraska, asked Gillespie to build one for him. Instead, Gillespie built four units to test the market. They were all sold before he assembled them.

Today, he sells 25 to 40 TracPackers annually. Units have been sold to farmers across the country as well as overseas.

Currently, he offers three models (to suit different tractor sizes from small utility to four-wheel-drive machines) for various makes. A Ridge Knocker attachment is available for smoothing out ridged fields.