:max_bytes(150000):strip_icc()/Zimmatic20Radial20Tire20Footprint-2-72fa62feb3514a29bad3e73475ac4361.jpg)

Radial tires have become ubiquitous on farm vehicles but a rarity on center pivots, where bias-ply rubber is the standard. Yet, "there have always been three major issues with bias pivot tires," points out Eric MacPherson of Dawson Tire and Wheel, Gothenburg, Nebraska, an ag tire specialty company. "They go flat, they get stuck, and they leave ruts. However, ruts have become a bigger issue, as machinery has gotten larger and field travel speeds have increased.

"We thought, 'Why don't farmers use radial tires on pivots? They already understand the benefits of radials on their other equipment.' "

The obvious answer is price.

"So about five years ago, we went to Trelleborg and asked them to build us a radial pivot tire that was affordable for pivots," MacPherson says, noting that the most popular pivot tire is the same size as some front tractor tires. "We suggested that they reduce the speed rating on irrigation tires, but we asked that they put more UV protection into them. As a result, we now offer a radial pivot tire that lists for around $30 more than the same size bias-ply tire."

As MacPherson explains, radial pivot tires offer a number of benefits that help offset the price difference, including better flotation and less compaction, since radial tires have a wider, flatter profile than comparably sized bias-ply tires.

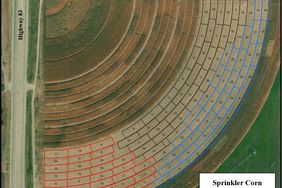

:max_bytes(150000):strip_icc()/Zimmatic20Radial20Tire20Wheel20Track-2-55b46ad4b7404ee1ad0be2e57391603f.jpg)

"That results in more surface contact area in the track, plus fewer rutting and wheel track depth issues as the season progresses," MacPherson says. He has since sourced radial pivot tires from other manufacturers.

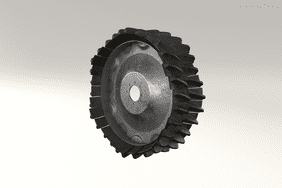

"During some of our tests, we were taking ruts that were running 8 to 14 inches deep down to 1 to 2 inches, just by switching to radials under the same soil and watering conditions. Plus, radials generally run at much lower air pressure (15 to 17 psi). Yet, due to their strong, flexible sidewalls, they can support the load of the pivot, even at these lower air pressures. This allows more soil contact area and increased traction in difficult conditions. A 320/85R38 radial has 60% more footprint than an 11.2×38 bias tire," he says.

MacPherson says radial tires are designed with a lot tighter bead-to-rim tolerance, as well. This helps eliminate rim slip in high-torque applications, which, in turn, helps eliminate one of the leading causes of flat tires in the field. Due to their design, radials carry a longer warranty of eight years compared with the typical five years on bias tires.

"I don't see that radials will ever take over the pivot tire market," MacPherson says, noting that radials account for about 30% of their pivot tire market. "There will always be applications, such as sandy soil, where a bias tire works just fine."

The benefits available from radial tires have convinced at least two pivot manufacturers to offer radial options. While Reinke offers a 320/85R38 radial tire from Titan, Lindsay offers Trelleborg radials sourced on all models.

"They're becoming a more popular option," says Wade Sikkink of Lindsay Irrigation. "In addition to their flotation and traction qualities, radials provide the smoothest rolling characteristics of any pivot tracking option, leading to less torque being transmitted back into the pivot driveline and tower span structures."

Because the load rating is much higher than standard six-ply tires, radial tires are also ideal for use on swing arm corners or other longer and heavier spans.

"We're seeing enough performance out of the radial tires," Sikkink says, "that we're recommending our customers take a look at that option before going with one of the multi-tire tower or corner options."