:max_bytes(150000):strip_icc()/img_569d3628647b8_51959-8c26df40a12a4c619409bfa6bce7e540.jpg)

Remember Tim Allen's character in the 1990s sitcom Home Improvement? His catchphrase was "More power!" That TV handyman would have loved Stephen Garver's shop crane.

After all, "it picked up a 4,500-pound engine and trans just like it was a toothpick, and it was stretched out to 20 feet," Garver reports. He's quick to advise, however, that the crane capacity must be respected. Fully extended to 41 feet, it will pick up as much as 1,500 pounds. Just 10 feet from the crane base or less, and it will lift 10,000 pounds. Respect, indeed! "Since the crane sits 20 feet from my overhead door, I can reach 20 feet outside if the load is light enough," he says.

Garver, who lives in Marion, Arkansas, thought a long time about the right crane for his existing 50×60-foot shop. He didn't want to risk stressing the structure by installing a tracked system, and he didn't want to be restricted to working only directly under the beam of a jib crane. Then inspiration struck, and Garver found a knuckle boom crane for sale on eBay.

You want to do what?

He faced challenges when he tried to consult with professionals about his installation and implementation ideas for the unconventional shop crane. When Garver phoned the boom truck manufacturer, eventually the rep did help him determine he'd need a 12-gpm pump with a 2,500-pound pressure rating to pop the crane's check valves. Garver quickly concluded that until there was a permanent power supply, he could operate his new crane by running two hoses out the shop door and plugging them into one of his tractors.

"I imagine when the rep hung up the phone, he said, 'You're not gonna believe this, but some redneck down in Arkansas is going to screw one of these things to the shop floor and drive it with a farm tractor,' " says Garver.

Overengineered is better

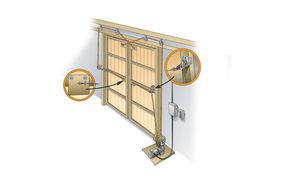

It's not screwed to the shop floor. The crane is bolted to a 14-stud structure at the bottom of an 8×8×6-foot cement base. By the time the concrete company finished pouring, "it was just a wheelbarrow short of 18 yards (70,000 pounds). Plus, there's rebar and the stud structure. The crane weighs about 7,500 pounds," he says. One consulting engineer confirmed Garver's estimate that a 13-yard base (7×7×7 feet) would be sufficient, but Garver went with the extra weight.

A permanent power system includes a 30-hp. electric motor, 12-gallon hydraulic pump, and a 40-gallon oil reservoir tank.

If you'd like to try this idea, Garver has two tips:

- Set the base on 10-inch I-beams, as he did, to allow access to the turntable for maintenance.

- Add remote control, which he plans to do next.

$2,500 winner

Garver is the next recipient of a $2,500 Firestone in-store credit offer for having his idea chosen as the Idea of the Month. Enter your idea for a chance to win.

More about Stephen Garver

Mechanic: In 1994, Stephen Garver opened his own shop to work on farm equipment, farm trucks, and other tractor trailers.

Roots: He grew up on his parents' dairy operation in Maryland.

Experience: Garver has been an IH dealership mechanic and an over-the-road truck driver.

Hobby: This IH enthusiast collects tractors with low and high serial numbers.

Wish List: Garver is researching and comparing brushless drills.

Pet Peeve: No-name parts are rejected by Garver, especially wheel bearings, U-joints, and steering components.

Email: garverequipment@aol.com

Article by Paula Barbour