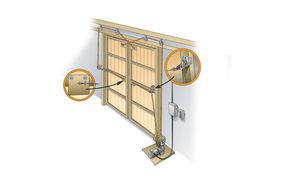

Tired of gravel flying everywhere when he cleared snow from his driveway, Hans Jess went to the shop this January to rectify the situation.

To gain additional clearance, he'd already beefed up the factory shoes six years ago. "They were probably all right for pavement, but nothing out on the farm is very level," he says. It wasn't enough lift, though.

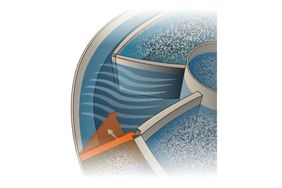

So he added a hydraulic cylinder for a third shoe, and now he has an optional 4 inches of lift. "That seems to be just right. Any higher, and it could twist the snowblower on its three-point hitch. It's high enough so I don't pick up gravel anymore from the crown of the road on our narrow driveway." Jess says he used the heaviest steel he could find to take the force and weight on that side of the blower.

MATERIALS: Steel plate from a moldboard plow, tubing off a cultivator, channels, cylinder

TOOLS: Welder, chop saw, grinder

Hans Jess

Second time: This is the second Idea of the Month from Hans Jess; his first was in March 2016. Like many AATF contributors, Jess enjoys fabricating improvements for his equipment in his shop.

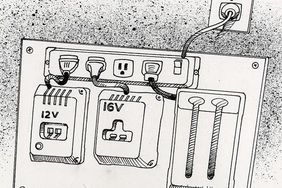

Career: He worked 19 years as a technical specialist for an electrical distributor and retired in 2014.

Farm: Jess and wife Lynn grow corn and soybeans in Olin, Iowa.

Family: Their two daughters and five grandchildren live in the area.

Son of immigrants: "My parents moved here when I was a little boy. They bought the place where I farm now in the 1960s," he says.

Email: hljfarm@netins.net

More Features

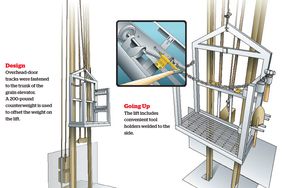

Adjustable: When removing snow from uneven surfaces, such as the crown of a driveway, having some flexibility is helpful, but not so much that it stresses the snowblower on a three-point hitch. Hans Jess finds a 4-inch range is just right. He is also able to adjust the angle from inside the tractor cab.

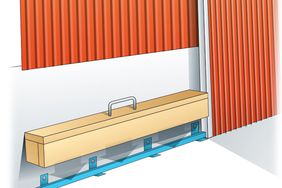

New Shoes: Factory shoes were reinforced with bolted-on shop-built shoes. The originals didn't lift the blade at all and were inadequate for use on gravel surfaces.

Heavy-Duty Mounting: Flat steel 2½ inches wide is welded to a 13⁄8 -inch solid square bar to form a leveling skid shoe. The bar is in a 1½-inch square tube welded to a bracket.