Make planting season go more smoothly with these handy ideas from our farmer readers, as seen in All Around the Farm®.

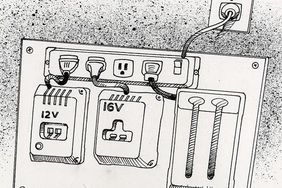

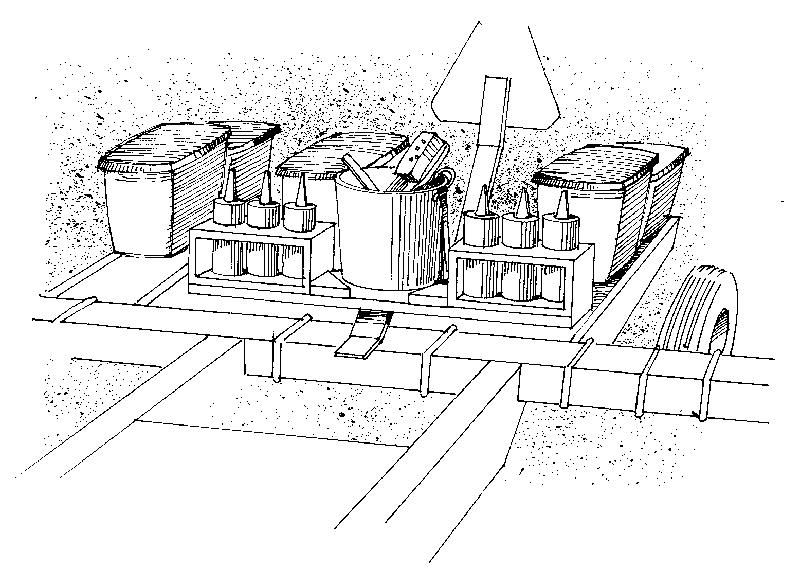

1. Graphite-holding rack

This handy rack is built of wood. It holds the powdered graphite Ken Miller uses for the finger planter on his farm near Rochelle, Illinois. He says that with this rack, he can reach the graphite bottles from either the front or the back. He also mounted a bucket in the center to hold a whisk broom, grain scoop, and a few other tools.

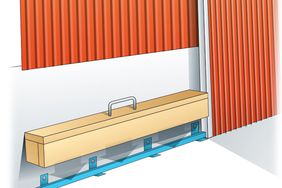

2. Lower steps to grain drill platform

After Jacob Roosa III of Milford, Delaware, became unable to step up on the back platform of my grain drill, he built a short ladder and attached it to the platform. At 31 inches long and 11 inches wide, it serves as a stepladder. When not in use, it's held in place with a tarp strap and a small safety chain. The rungs are made of ⅝-inch rod.

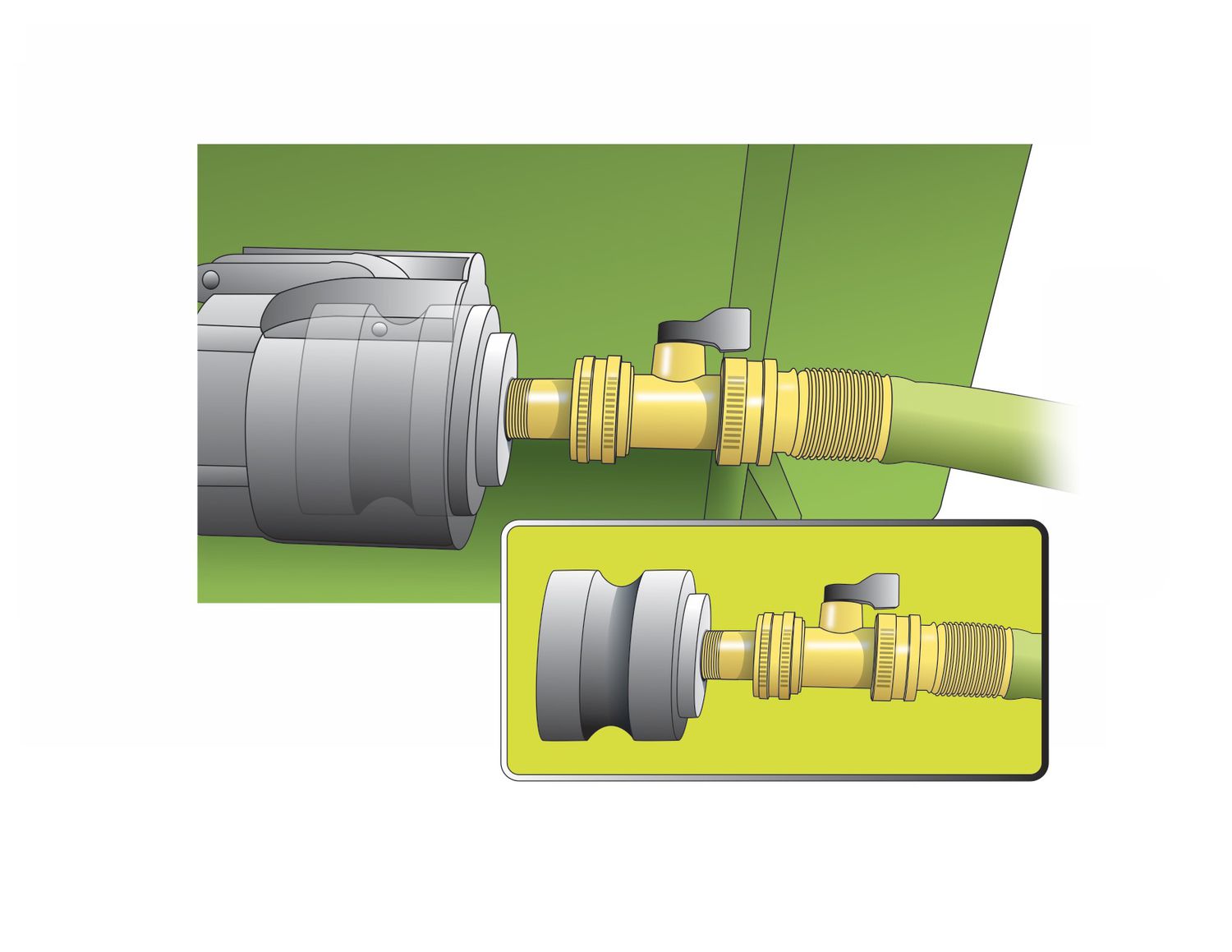

3. Save time on small fills

When Dennis Kirtz of Hector, Minnesota, calibrates the planter or crop sprayer and needs only a small amount of fill to finish around the yard, he no longer has to get out the larger water truck. Instead, he goes to a water hydrant. A banjo coupler connects easily as an adapter from the garden hose to the 2-inch hose fitting on the planter or sprayer. This saves a lot of time when only 5 to 10 gallons are needed.

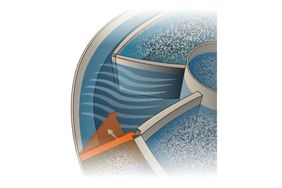

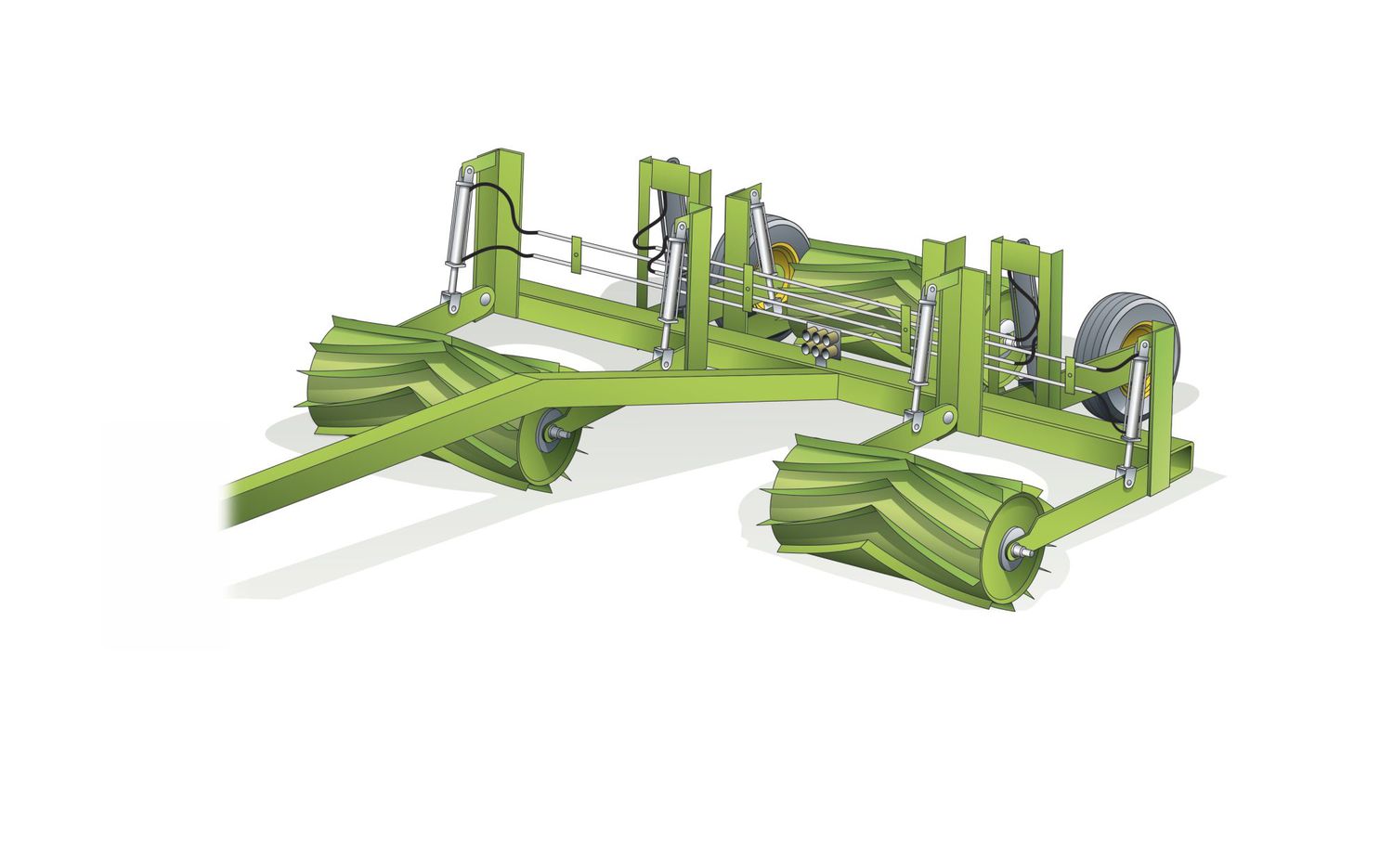

4. Pull-behind crop roller

Preferring not to use herbicide to kill his cover crops, Stephen Aberle of Sabetha, Kansas, built a roller that terminates rye, triticale, and oats. The rolls are mounted with hydraulic cylinders. Extending six cylinders about two thirds of the way allows the rolls to flex to follow the contour of his terraced land. At 40 inches high, the tongue will clear the wheels on a drill. A chevron pattern in the rollers helps cut down on bouncing. Aberle can retract the roller to a width narrower than the drill for transport. "I had to add a pennant on each corner so I can see where the thing is," he laughs. "I can't see it behind the drill. It works great. I can also pull it without the drill," he says.

The rolling action smashes stalks of cover crops in the same way a hay crimper does. If rye is at pollinating stage or later, this will kill it. "When my sorghum sudan cover crop was 6 to 8 feet tall, I rolled it before it went to seed. The stalks are so thick, it didn't kill it, but it prevented production of viable seed," says Aberle. His design is based on a 15-foot three-point roller the Natural Resources Conservation Service rents out. Rodale Institute built the first one. "You can get some of the blueprints on the web," he says. He used the following parts:

- Wheels from a used planter

- Electrohydraulic controller from a used chopper that runs three hydraulic circuits

- 9 hydraulic cylinders

- 6- and 7-inch square tubing

- Factory-built U-bolts and straps

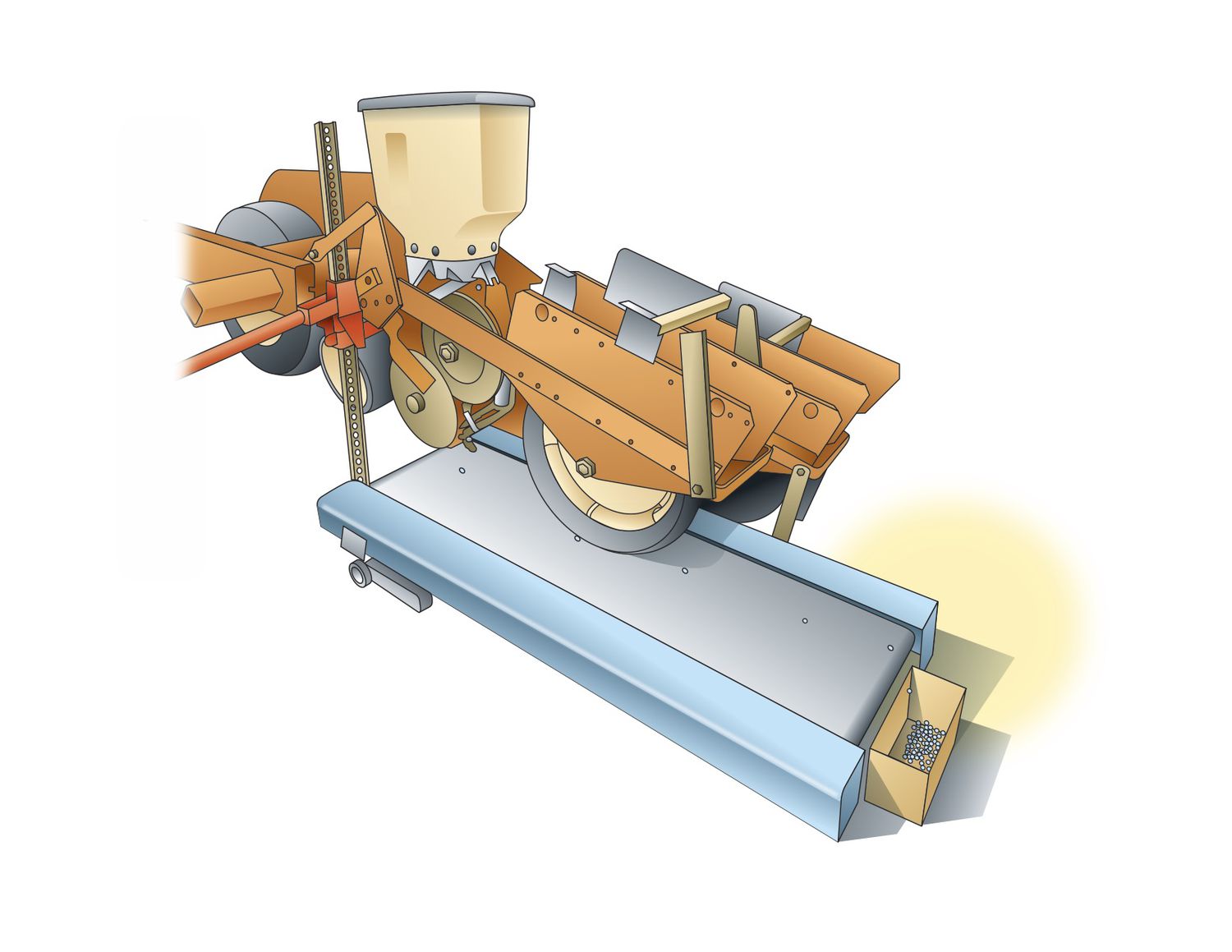

5. Old treadmill prevents problems before planting

With the front bar off an old treadmill, Richard Jagels of Bulh, Idaho, can check his planter's seed rate. Seed drops between the disks while the back drive wheel is powered by the treadmill. It's a great way to check if the plate is too large, which makes it double up seed. He can also mark the wheel to see how many kernels are being planted for a more accurate population count. The treadmill will go fast enough to test seed-disk filling at a high speed.

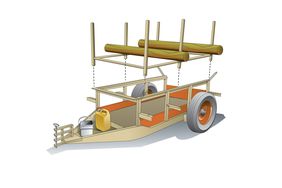

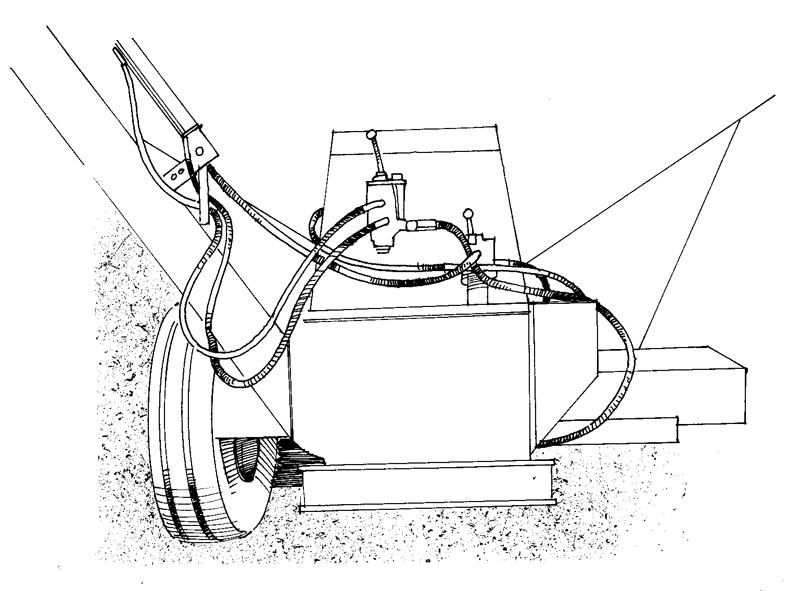

6. Seed or fertilizer tender

Tired of having to crawl into the gravity box to shovel fertilizer into the auger when filling his planter, George Tipler of Oshkosh, Wisconsin, took action – he converted a used fertilizer spreader to a tender. He purchased a folding fertilizer auger and removed the spinner from the rear of the fertilizer spreader. Then he attached the folding auger to the rear of the trailer and installed a hydraulic motor to drive the apron. The tender has a roll top.

7. Tongue extension

A drawbar mounted on a planter pulls a 1,500-gallon tank of fertilizer during planting for John James of Redfield, South Dakota. The tubing will fit between two row units. James says he pulls a pin, backs up a little, and the tube slides under the tank. This brings the tank wagon right next to the planter on more compact systems, he says. He also reports that, by using this method, his clothes stay free of fertilizer or chemicals.

8. Seed box lids lost no more

Like many other people, Robert Bremel of Hillpoint, Wisconsin, was having trouble losing the lids on his corn planter's seed boxes. Then he put the hook portion of 1.5-inch-long pieces of 1-inch self-adhesive Velcro under the lids and the same size pieces of the loop half in the corresponding spot on the back of the seed box in the middle of the handle. He advises making sure the area is clean and dry so they stick.

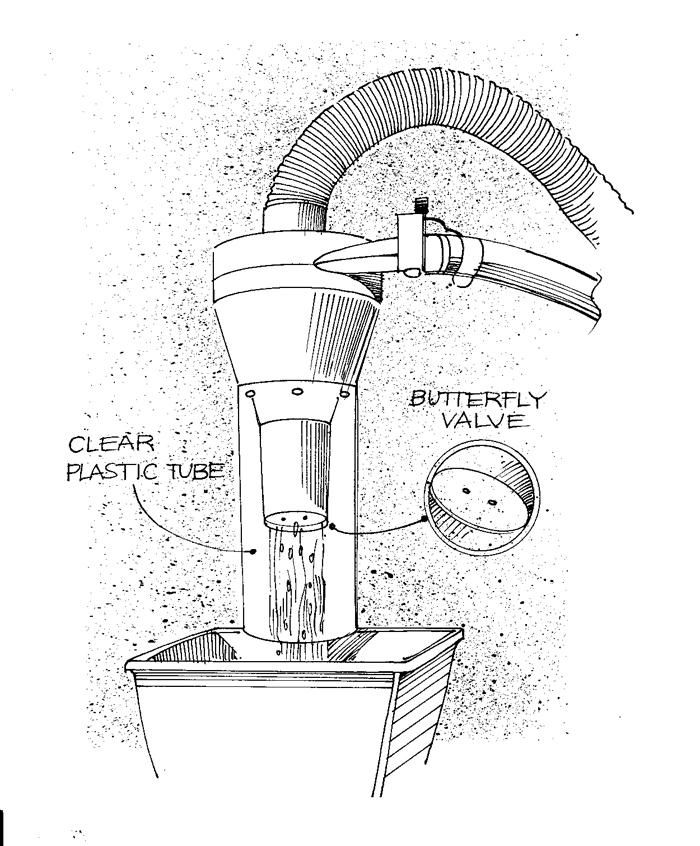

9. Planter box fill

Gary Houdek, Chapman, Nebraska, extended the tube on his Seed Vac and added a butterfly valve. Now he shuts off the valve between boxes, switches to the next hopper, and seed fills the black cone. At the next hopper, he opens the valve and the seed empties as the flow continues. He also added a clear plastic tube so seed won't splatter during a fill.

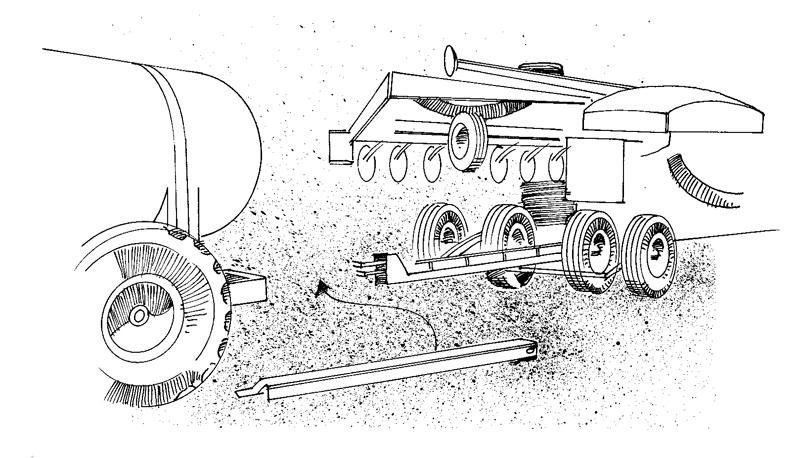

10. Seed and revitalize all at once

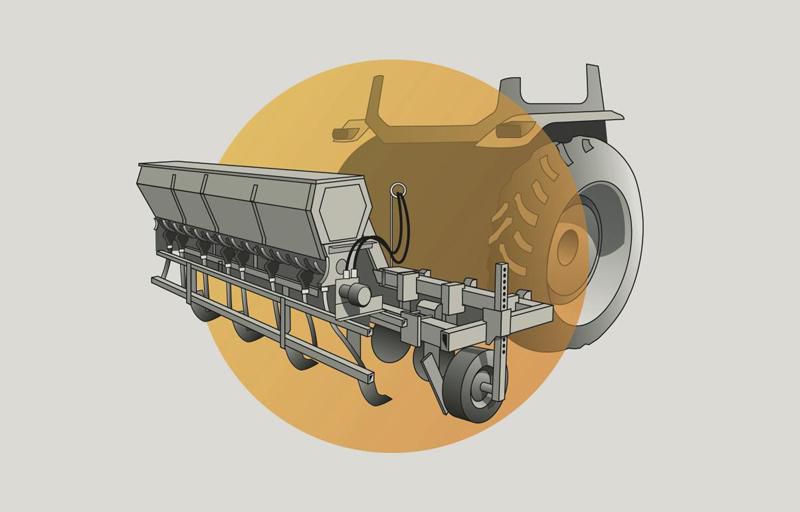

Virgil Wiatrek came across an out-of-service grain drill and adapted it to work with the pasture renovator on his Stockdale, Texas, farm. Now he uses this combination to both renovate and sow rye or oat seeds in just one trip, which saves him time, fuel, and labor. He says a person could use it for other small grains or grasses.

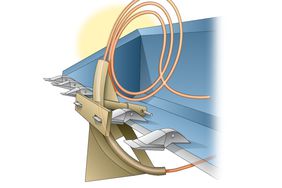

11. Planter mark more visible at night

Richard Westerfeld of Crawford, Texas, build this light bracket out of a 9-foot-long piece of pipe and attached it to the bottom of his tractor weights. The lights are down low, away from the center, and pointed across the planter mark. That way they create a shadow that falls across the marker trench. It's visible, he reports, from nearly as far away as the lights shine.

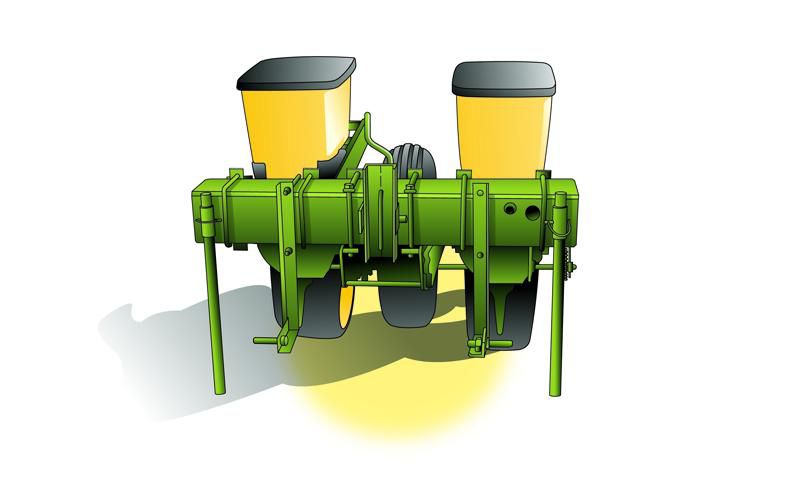

12. Plant in skips or drowned out places

Mattoon, Illinois, farmer Duane Seaman wanted a one- or two-row planter to plant in skips or drowned out places. So he bought a wing from a 12-row finger pickup, shortened the bar for two rows, and built a hitch to attach it to the three-point hitch of his utility tractor. The driveshaft comes out to the end of the bar. A different sprocket could be used to change population, he says.

13. Apply inoculants with less hassle

Here's another way to apply inoculants from Bob Timp of DeSmet, South Dakota. He cleaned out an old Dectomax container and filled it with inoculant. It's easier now, he says, to measure and mix and much more convenient than using the plastic cup that comes with the inoculant. Just set the gun to the correct setting, and spray it over the seed in each planter box, says Timp.

14. Distribute graphite

A 3x12-inch-long garden auger does a good job mixing graphite throughout seed boxes at planting time, according to Fred Ifft Jr. of Fairbury, Illinois. He uses an 18-volt impact tool to turn the auger at a slow speed. He says he's also welded a quick-attach end to the drive end of the auger for faster implementation.