It's highly unlikely that his current shop heater will warp like the wood-burning stove he once used, says Vernon Hege of Trementon, Utah.

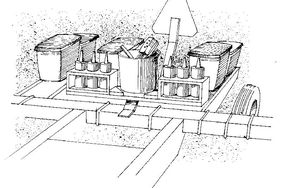

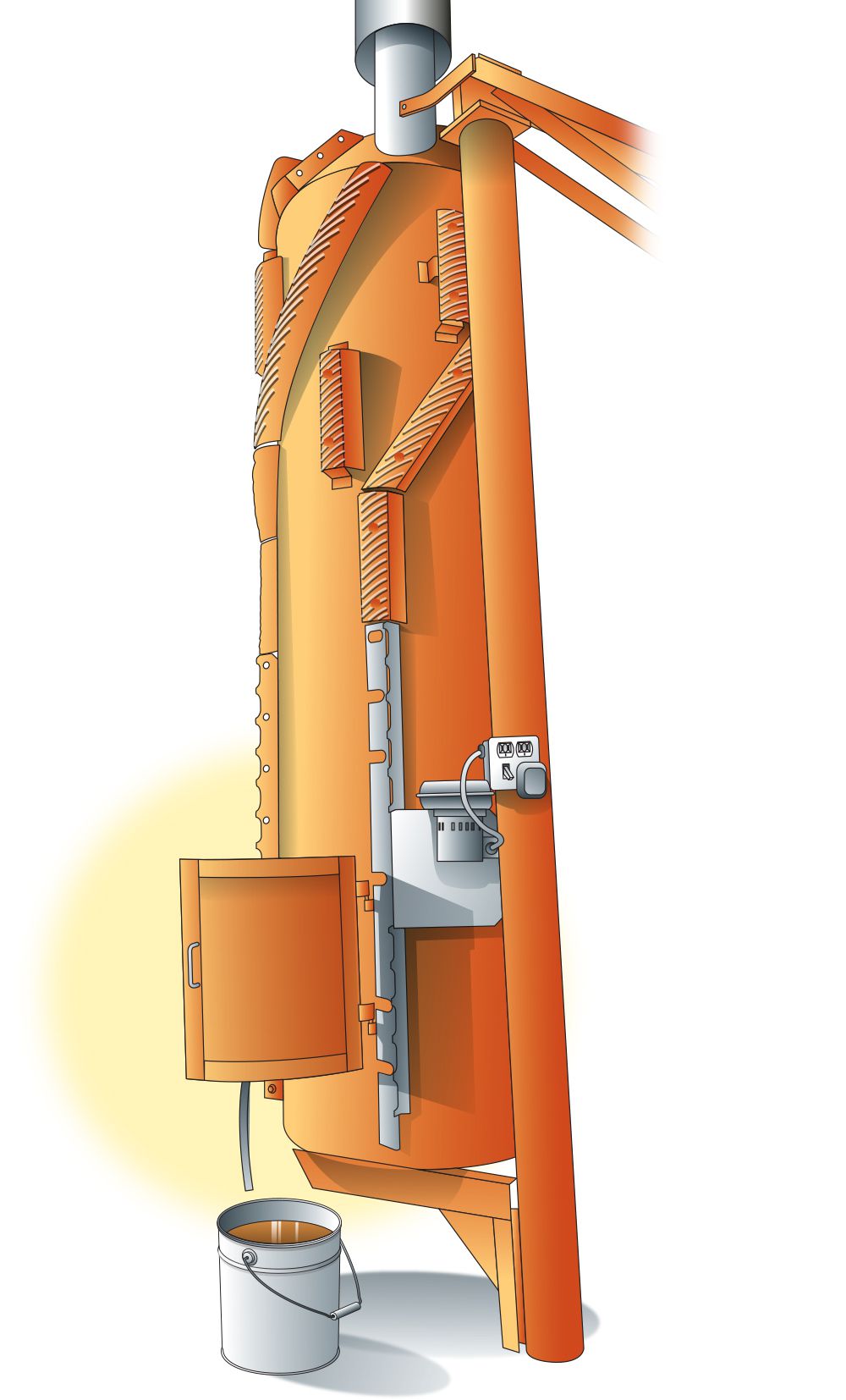

In the bottom of a combine cylinder-turned waste oil burner is an upright 8-inch-long, ¾-inch bolt centered in a steel plate. Three stacked brake drums surround the plate and bolt and, after a small wood fire here gets the bolt hot, a HECO brand variable-speed gear pump outside the rotor brings in oil to drip onto the bolt. The connecting hose has a screen that filters out steel shavings.

A 2-inch pipe equipped with a squirrel cage fan outside the rotor brings air in, and an elbow aims air down into the brake drums. There is also a piece of steel on the face of the fan to regulate the volume of airflow.

Hege jokes, "It's so warm, we stand around talking instead of working."

MATERIALS: Rotor, pump, fans, hose, steel plate, bolt

TOOLS: Cutting torch, welder

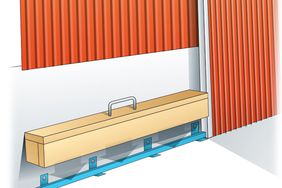

Openings: While holes cut in the rotor's baffles let the exhaust out, the baffles also slow the exhaust down to create more heat. A door cut in the bottom gives access to the combustion area.

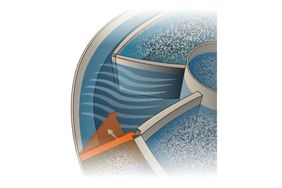

Radiant Heat: The rasps on the exterior work as fins to distribute heat evenly throughout.

Vernon Hege

Family operation: Vernon Hege and his dad, Nathan, have a 180-head birth-to-finish herd of Holsteins at the western edge of the Rocky Mountains.

Other enterprises: Besides growing 350 acres of corn, alfalfa, wheat, barley, and safflower, they offer custom haying and meat processing of wild game, such as elk and deer, and domestic animals. The Heges also raise a small number of hogs for direct sales of pork, along with beef.

New family: Married in 2016, Hege and his wife, Rosella, have two children. Son Leroy turns 2 in June, and daughter Rosellica is 5 months.