:max_bytes(150000):strip_icc()/IOM_welding20cart-2-2000-a6372735d1e646ff9b154f7809324239.jpg)

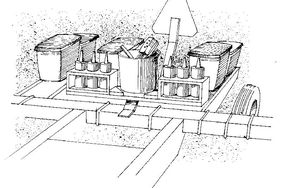

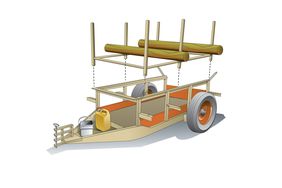

To design a welding cart to his own specifications, Randy Myers started by buying the least expensive model he could find.

"Then I bought no-flat wheelbarrow tires and changed the axle," he says. "The wheels are spread out plenty so it won't flip, and most of the weight is on the bottom." Myers notes that the wider wheelbase and larger wheels let him roll the cart on unpaved surfaces.

"I also built some shelves sized for the equipment I already had." That equipment includes his flux core MIG welder and inverter stick welder, because they can be used outdoors. The smaller stick welder sits on the top shelf, and other shelves accommodate all the equipment he needs. Having two grinders, his helmet, and all the cords and cables he needs eliminates extra steps.

"Now, if I need to work on a chisel plow or disk or something else I don't want to pull into the shop, I roll this out to it," he says.

Myers says this project took him about two days to complete last fall. He only had to buy the cart and its new wheels.