:max_bytes(150000):strip_icc()/hydraulic20bearing20press-2-2000-78a8e9d8344440d8bcbe9230984cc784.jpg)

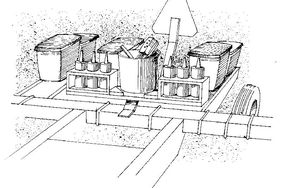

Tasked with rebuilding a combine's rear-axle hub, the first thing William Horning and his coworkers had to do was press the axle shaft out of the hub. However, the flange on the axle where the wheel bolts on was too large in diameter to drop between the rails of the shop press.

"We put our heads together that day and came up with this method instead," says the Lancaster County, Pennsylvanian.

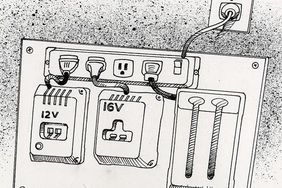

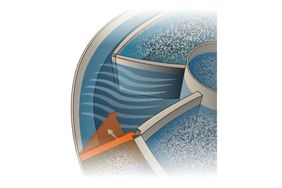

Horning made two slotted brackets to attach to the hub. Then he draped ½-inch chain up and over a bottle jack; a link on each end hooked through the slot in each bracket. The bottle jack pushed the axle down out of the housing while pulling up on the hub.

A length of pipe slightly larger in diameter than the top of the jack has a piece of channel iron welded to it, cupped upward to keep the chain from slipping.

On each side of the jack is a slotted bracket attached by two bolts to the axle hub. They are wide enough to hold ½-inch chain.

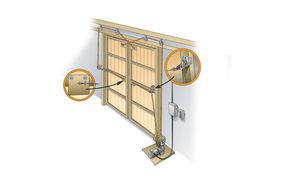

"The basic principal can be applied elsewhere. It can be used whenever something is too big and bulky to get set up in a shop press." Horning says he's heard of others using a bottle jack and chain to straighten a frame on an implement or the tongue of a wagon, and he's seen the setup used on final drives and gearboxes.

6-minute removal time

Honing says that setting up the chain, jack, etc., takes about five minutes, and the actual jacking procedure can be done in less than 60 seconds.